Science Behind Adjustable Temperature Limit Switches in Precise Heat Control Applications

Understanding the Role of Temperature Regulation in Heating Systems

Temperature control is one of the vital elements in the safe and efficient operation of electrical appliances that generate heat. From household kettles to industrial heating equipment, maintaining suitable temperature levels ensures both performance and safety. At the core of this regulation system lies the Adjustable Temperature Limit Switch, a component specifically engineered to monitor, control, and limit temperature within a preset range. This mechanism prevents overheating, enhances energy efficiency, and extends appliance lifespan, making it indispensable in precision heat control.

How Adjustable Temperature Limit Switches Work

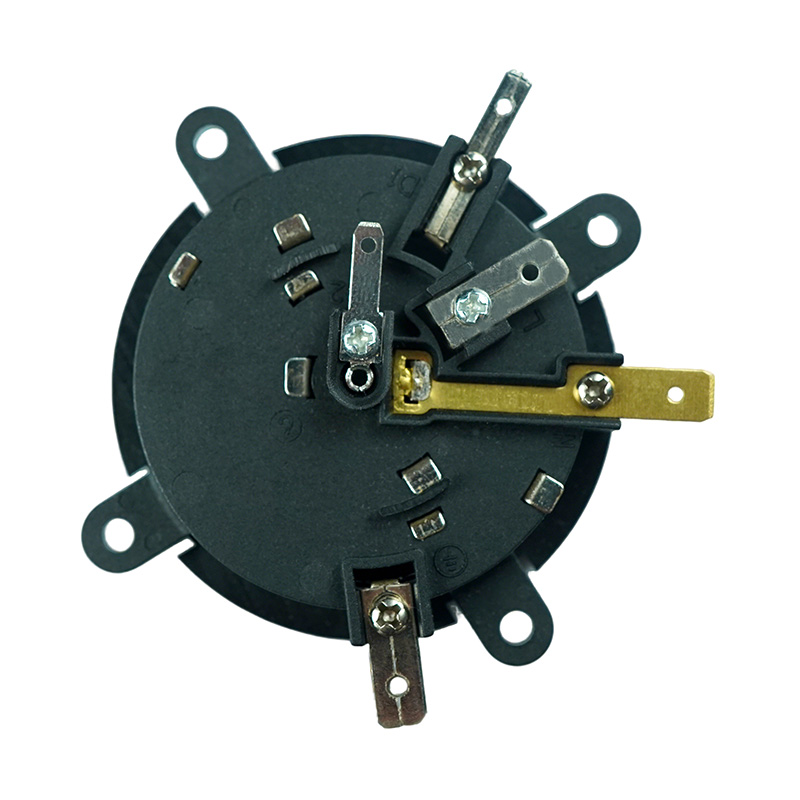

An Adjustable Temperature Limit Switch operates by sensing the temperature in real-time and interrupting the electrical circuit once the temperature exceeds a user-defined threshold. Unlike fixed thermostats, adjustable switches allow users or engineers to set the desired cutoff point, offering customization for different operating conditions. These switches typically use bimetallic strips or thermistors that react to heat by changing shape or resistance. The change triggers a mechanical or electrical action that cuts power to the heating element, effectively keeping the temperature within safe limits.

Applications in Consumer and Industrial Equipment

These switches are widely employed in appliances requiring high-precision temperature control, such as ovens, space heaters, water boilers, and laboratory instruments. In the case of electric kettles, the use of an Adjustable Temperature Limit Switch enables users to heat water to specific temperatures ideal for different beverages, such as tea or coffee. This level of accuracy is not only convenient but also energy-saving. In more complex applications like HVAC systems or industrial incubators, these switches help maintain steady environmental conditions without manual intervention, reducing system stress and ensuring consistent output quality.

Integration with Anti-Drying Safety Mechanisms

Many modern heating devices, particularly electric kettles, incorporate both temperature control and safety systems to guard against misuse. One such safety feature is the Anti-Drying Kettle Thermostat Switch, which prevents the appliance from operating when there is no water inside. This switch typically works in tandem with the adjustable temperature control system, ensuring that the heating element is disabled under dry conditions, which could otherwise cause component damage or fire. By integrating these systems, manufacturers create appliances that not only perform efficiently but also prioritize user safety.

Benefits of Precise Heat Control for Everyday Use

Accurate temperature management delivers tangible benefits. Appliances that include an Adjustable Temperature Limit Switch operate with greater energy efficiency because they avoid unnecessary heating. They also offer more comfort and convenience by allowing users to tailor the appliance's behavior to their needs. Meanwhile, the addition of an Anti-Drying Kettle Thermostat Switch offers peace of mind by ensuring automatic shutdown when dry conditions are detected. This dual approach of precision and safety sets a high standard for appliance performance in modern households and professional settings.

Conclusion: A Smart Combination of Control and Protection

The advancement of heating technology relies heavily on the development of intelligent components like the Adjustable Temperature Limit Switch and the Anti-Drying Kettle Thermostat Switch. These technologies demonstrate how science and engineering work together to achieve a delicate balance between user customization, energy efficiency, and operational safety. As demand grows for smarter and more reliable appliances, these thermal protection mechanisms will continue to play a critical role in shaping the future of heat control systems.

English

English  中文简体

中文简体  Español

Español