How Dry Boil Protection Kettle Part Coupler Works

Introduction to Dry Boil Protection

The Dry Boil Protection Kettle Part Coupler is an essential safety component in modern electric kettles, designed to prevent the kettle from operating when there is insufficient water. Dry boiling can cause overheating, damage to the heating element, and even potential fire hazards. By integrating a coupler that can detect water levels, manufacturers ensure that kettles automatically shut off when the water falls below a safe threshold. This not only protects the appliance but also provides peace of mind to users during daily operation. Understanding the principles behind this mechanism is important for both appliance designers and consumers.

Water Detection Mechanism

The core function of the coupler is to monitor whether there is an adequate amount of water in the kettle. Most dry boil protection systems rely on either a bimetallic thermal sensor, a float-based switch, or a combination of both. In bimetallic systems, the coupler is mechanically linked to a metal strip that responds to changes in heat caused by water evaporation. When the kettle is empty, the thermal sensor heats up more quickly, triggering the coupler to break the electrical circuit and cut off power. Float-based designs, on the other hand, detect the presence of water through mechanical displacement. A small float rises or falls with the water level, mechanically engaging or disengaging the coupler to allow or prevent electricity from reaching the heating element. Both systems are highly reliable when designed and installed correctly.

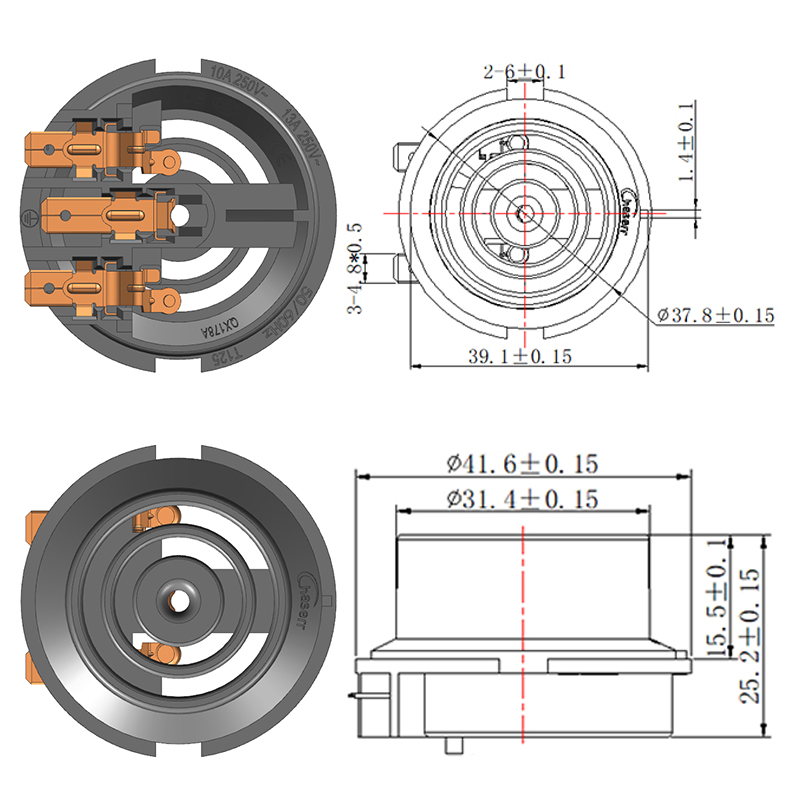

Coupler Integration with Kettle Base

Proper integration between the coupler and the kettle base is critical for accurate water detection. The coupler must be precisely aligned with the contacts on the base circuit board to ensure that the power supply is interrupted immediately upon detecting low water levels. Misalignment can cause delayed response, potentially allowing the kettle to continue heating after the water has evaporated. Some advanced designs also incorporate spring-loaded contacts or guided slots to guarantee consistent positioning. This mechanical reliability enhances the coupler’s ability to respond swiftly and protects both the kettle and its user.

Electrical and Safety Considerations

In addition to mechanical alignment, the electrical performance of the coupler is key to its function. The contacts must conduct sufficient current to power the heating element under normal conditions, but must reliably open the circuit without arcing when triggered. Some couplers also include insulation or flame-retardant materials to improve safety. Proper maintenance, such as keeping contacts clean and ensuring the coupler is free from corrosion or debris, ensures long-term reliability. A well-maintained coupler not only prevents dry boiling but also reduces the risk of electrical faults or component failure over time.

The Dry Boil Protection Kettle Part Coupler prevents dry boiling by detecting water levels through thermal or mechanical means and interrupting the electrical supply to the heating element. Its proper integration with the kettle base and careful electrical design are essential for reliable performance. By understanding how this coupler works, users and designers alike can appreciate its role in enhancing kettle safety, preventing damage, and extending the appliance’s lifespan. Ensuring precise alignment, clean contacts, and reliable mechanical function are the keys to achieving effective dry boil protection in electric kettles.

English

English  中文简体

中文简体  Español

Español