Ensuring Proper Mechanical and Electrical Coupling Alignment

Importance of Accurate Coupling

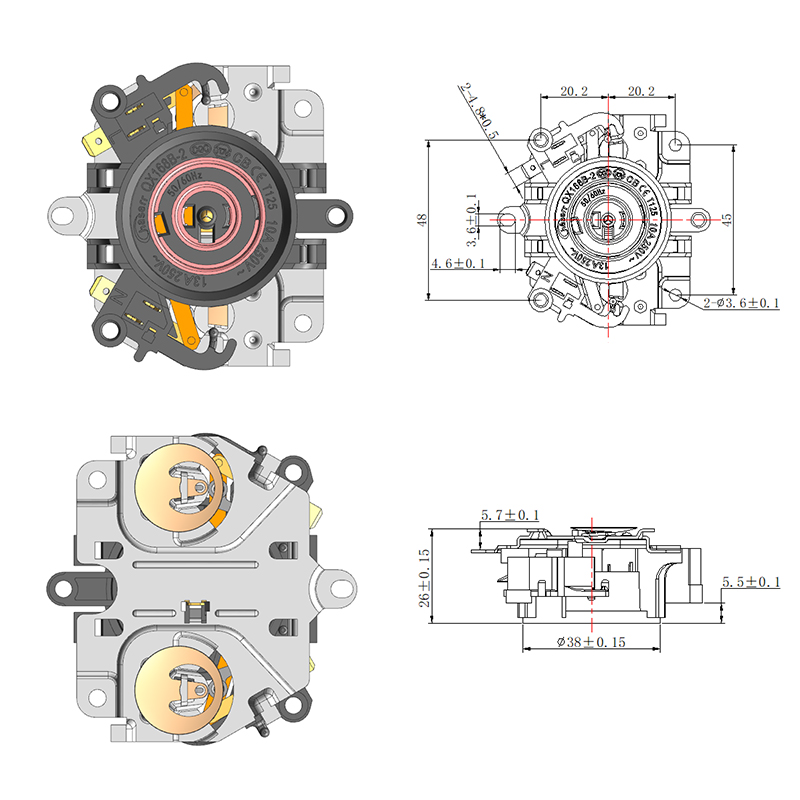

The Kettle Thermostat Coupler serves as a critical interface between the kettle’s heating system and its base circuit board. Proper mechanical and electrical alignment is essential to ensure the kettle operates safely and efficiently. When installed incorrectly, misalignment can cause inconsistent temperature readings, incomplete power transmission, or even permanent damage to the coupler or circuit board. The design of kettle couplers relies on precise engagement with contacts and a secure fit within the base to maintain both mechanical stability and reliable electrical connectivity. Understanding these requirements is the one step toward ensuring safe operation.

Mechanical Alignment Considerations

Mechanically, the coupler must fit snugly within its designated slot on the base. Most kettle designs feature alignment guides, such as grooves, tabs, or notches, which prevent rotational movement and ensure that the coupler seats correctly. The depth and orientation of the coupler are critical, as even a slight tilt can prevent the thermostat from making proper contact with the heating element or the circuit board. In addition, the physical stability of the coupler during operation is essential to prevent wear from vibration or repeated insertion and removal of the kettle. Ensuring that the coupler clicks or locks into place as designed is a simple way to confirm mechanical alignment before testing electrical functionality.

Electrical Contact Requirements

Electrically, the coupler must establish a secure connection between the heating element and the control circuitry. This involves precise alignment of conductive pads or terminals so that voltage and current pass without resistance or intermittent contact. Poor electrical alignment can result in arcing, overheating, or unreliable thermostat activation. Care should be taken to inspect the contact surfaces for debris, oxidation, or damage before installation. Some designs recommend lightly cleaning contacts or applying a small amount of conductive grease to improve performance and prevent corrosion. Ensuring firm and consistent contact between the coupler and the circuit board terminals is key to maintaining proper operation and longevity of both components.

Installation and Testing

During installation, the kettle should be placed on the base and gently pressed down while ensuring that the coupler aligns with the guiding slots. A tactile or audible click often indicates that the coupler has seated correctly. After mechanical installation, electrical testing is recommended to verify continuity and proper thermostat response. Using a multimeter to check the circuit can help detect misalignment issues before full power is applied. Careful attention during this process prevents damage to both the coupler and the base circuitry and ensures that the kettle operates safely during normal use.

Long-Term Reliability

Regular inspection of the coupler and base connection can help maintain reliable performance. Over time, repeated insertions or accidental impacts can slightly loosen the fit or introduce oxidation on electrical contacts. Periodic cleaning, careful handling, and ensuring proper alignment each time the kettle is placed on its base can extend the life of the coupler and prevent operational failures. By maintaining both mechanical and electrical integrity, users can enjoy consistent kettle performance and reliable automatic temperature control.

Proper mechanical and electrical alignment between the Kettle Thermostat Coupler and the base circuit board is essential for safe and efficient kettle operation. Paying attention to physical fit, contact quality, and careful installation ensures accurate temperature control and long-term reliability. By following manufacturer guidelines and conducting simple inspections, users can prevent common issues related to misalignment and ensure suitable performance of their kettle system.

English

English  中文简体

中文简体  Español

Español