- Bimetal Thermostat

-

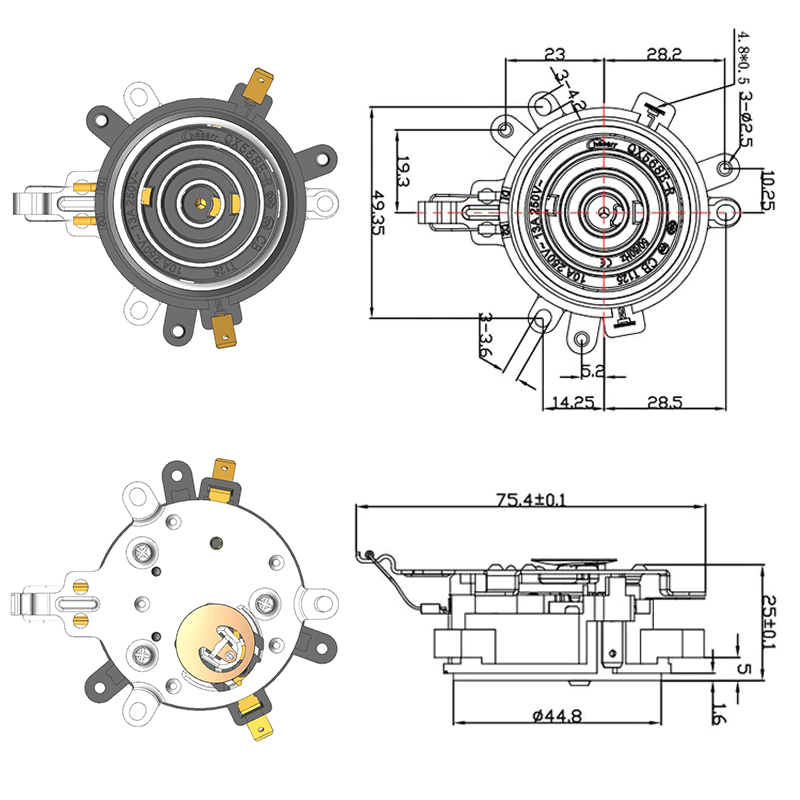

Steam Kettle Thermostat Switch

-

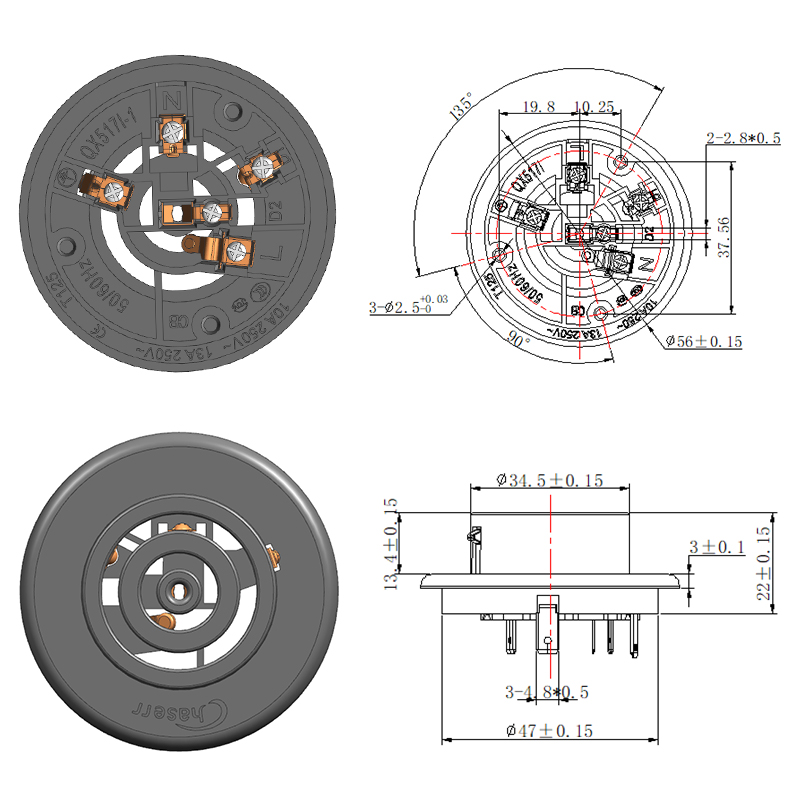

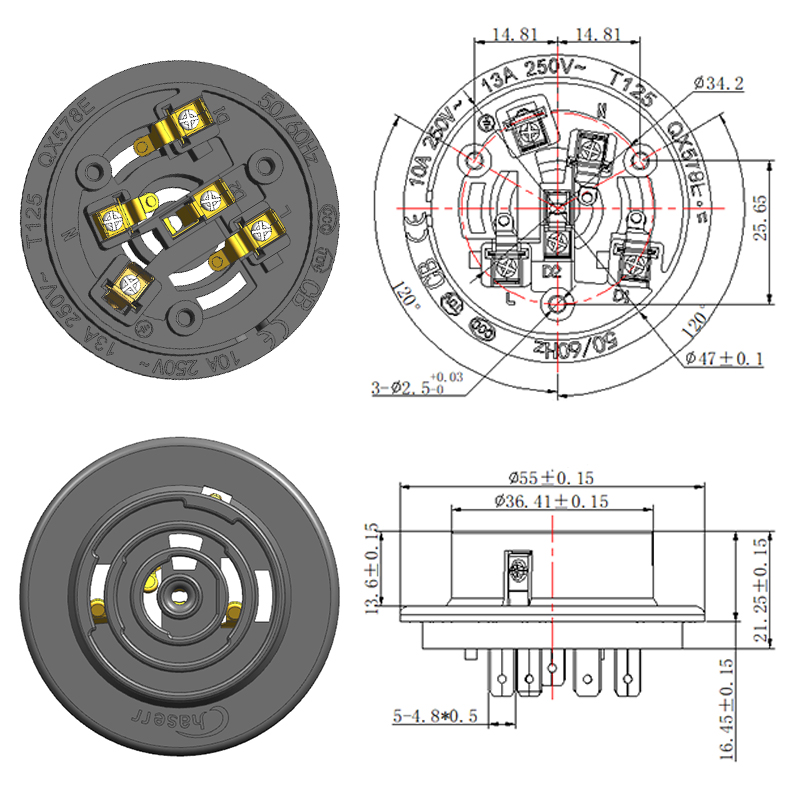

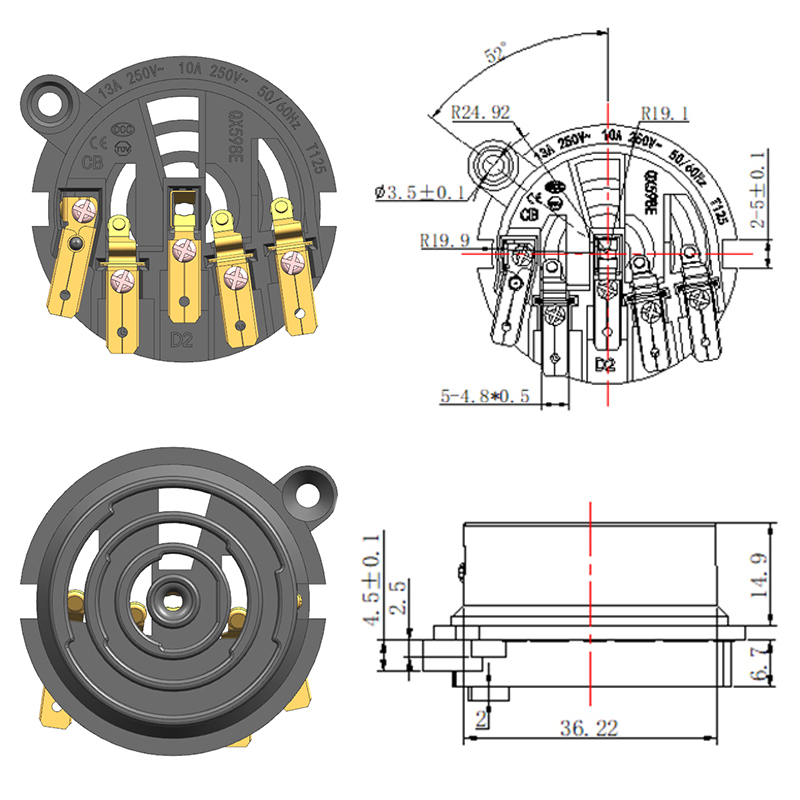

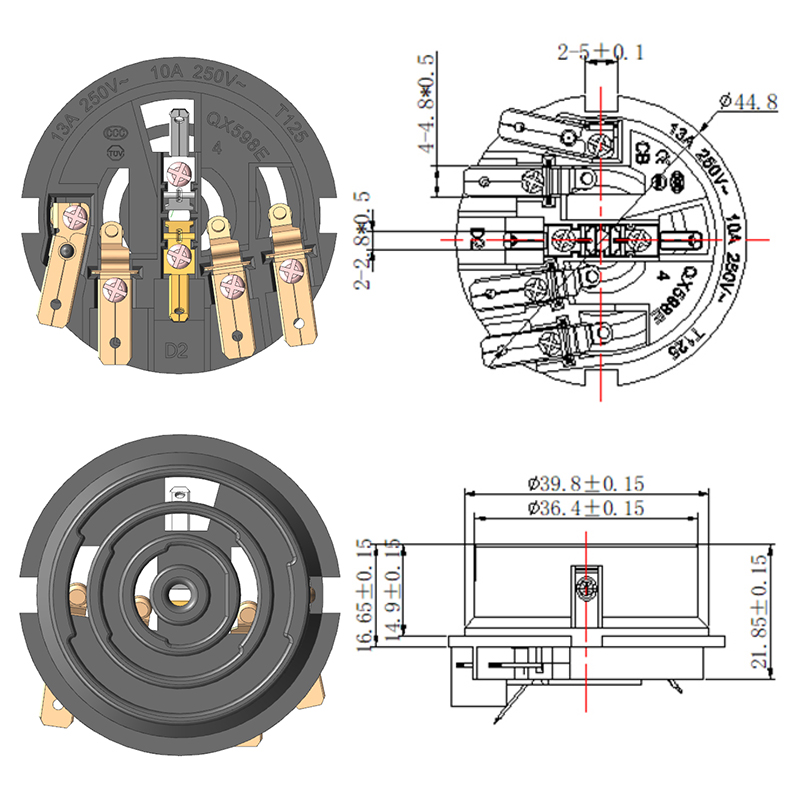

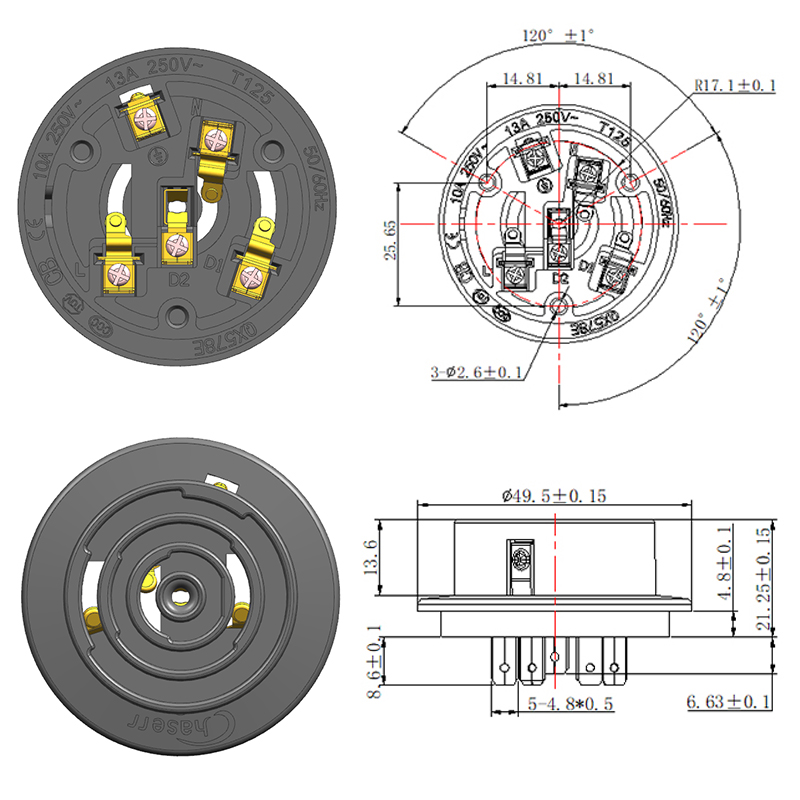

Kettle Thermostat Coupler

- Adjustable Temperature Kettle Coulper

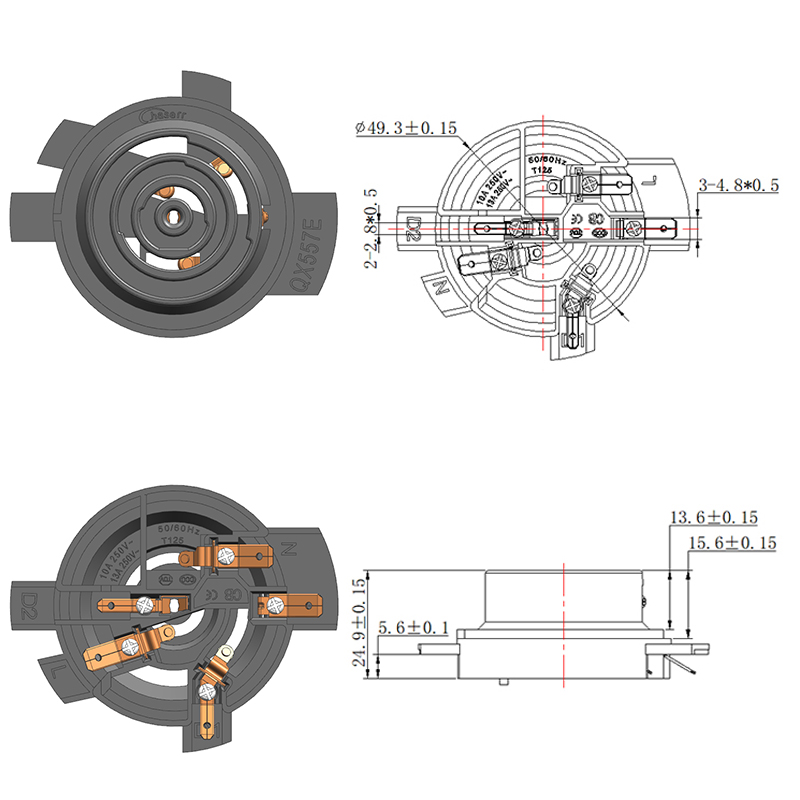

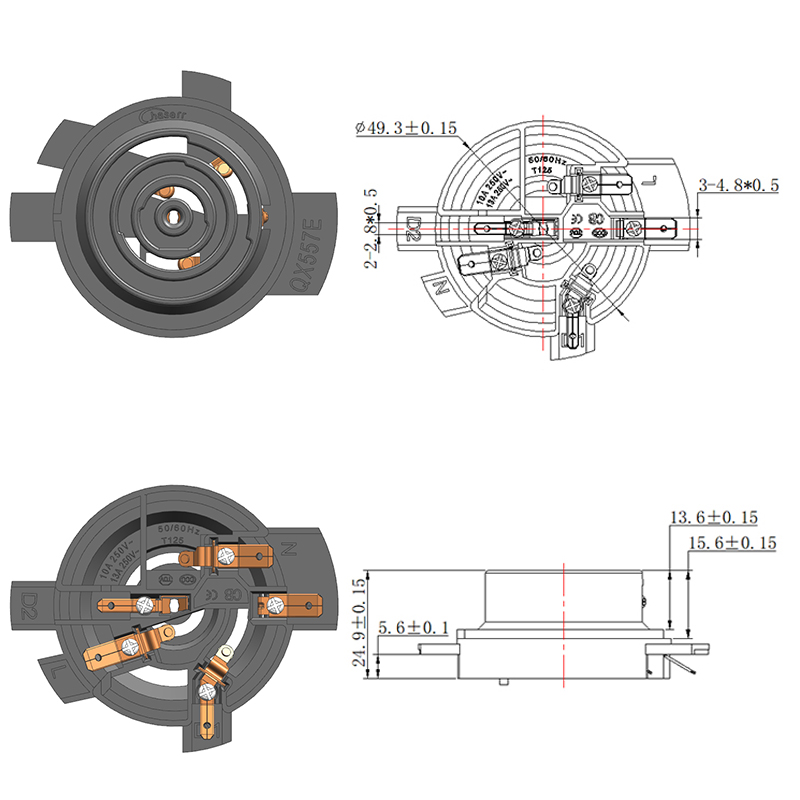

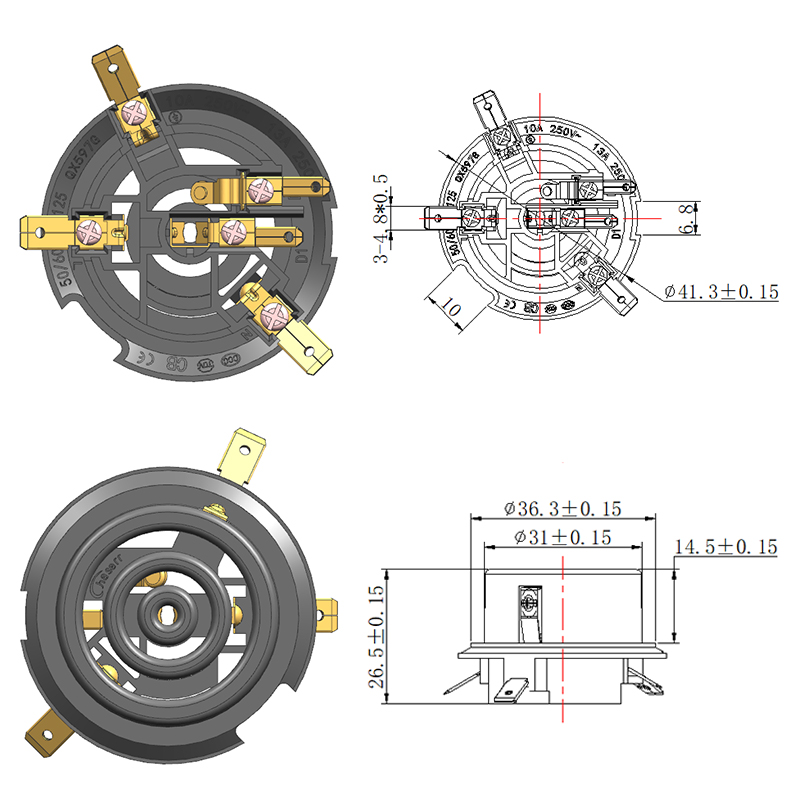

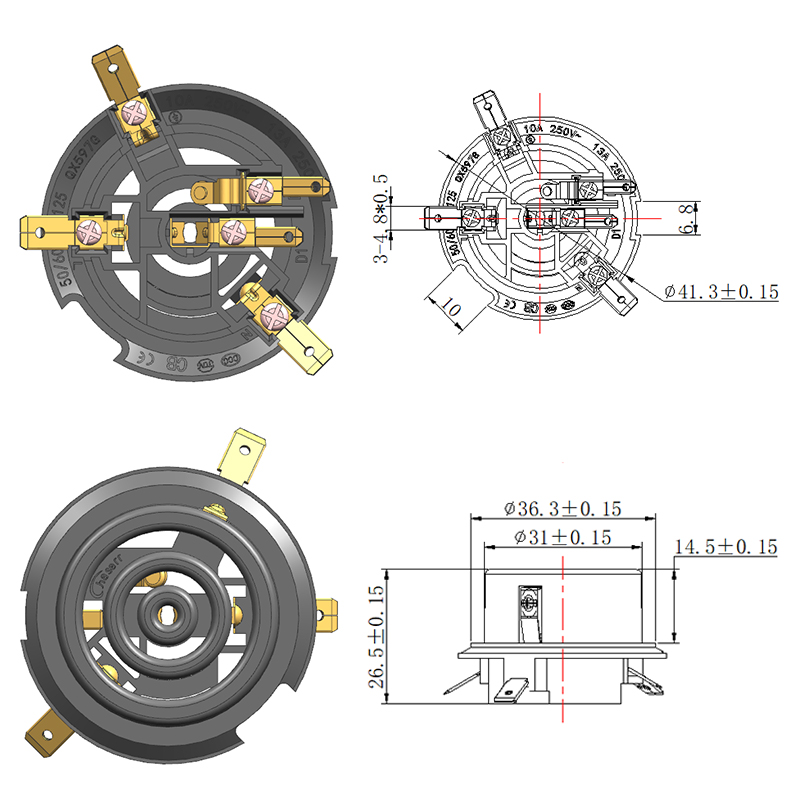

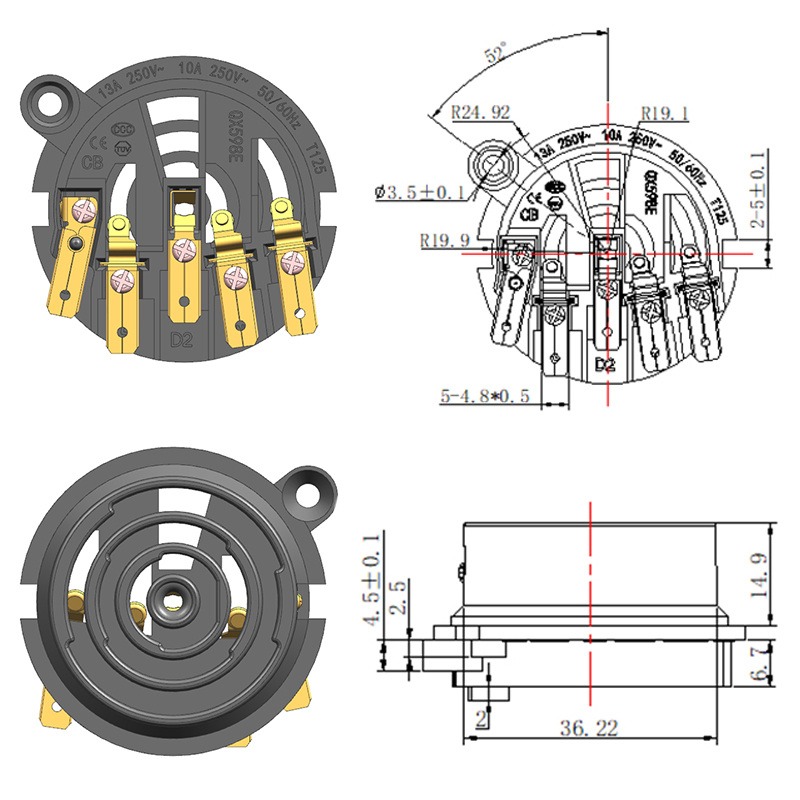

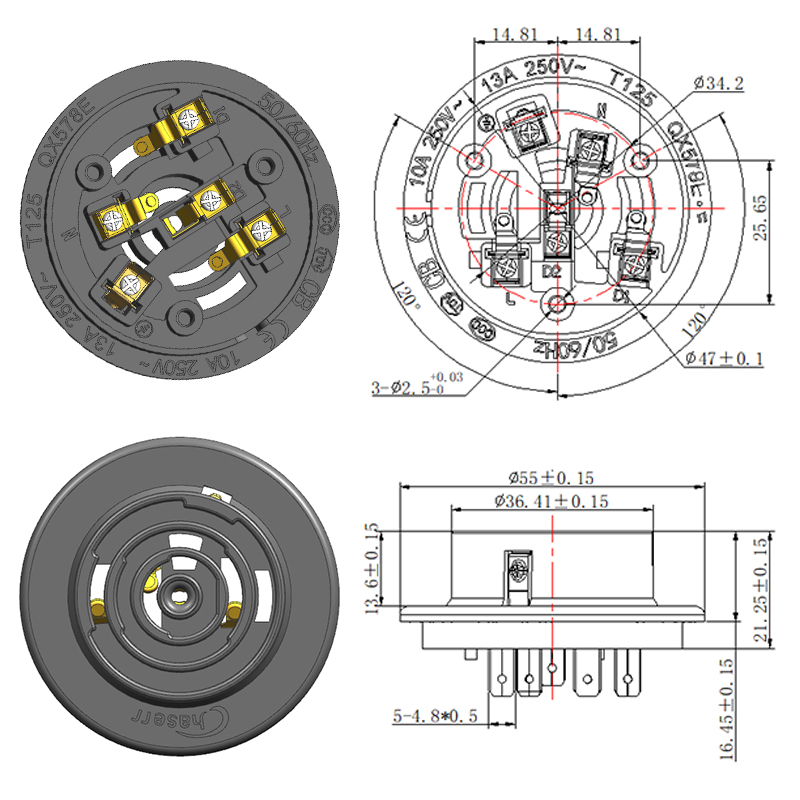

- Two-Piece Kettle Thermostat Coulper

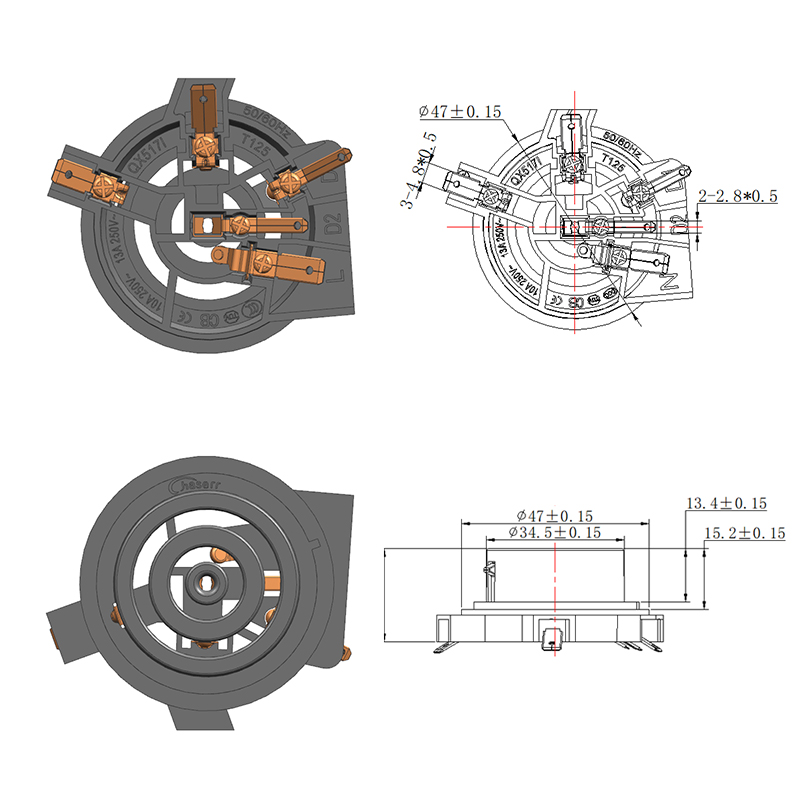

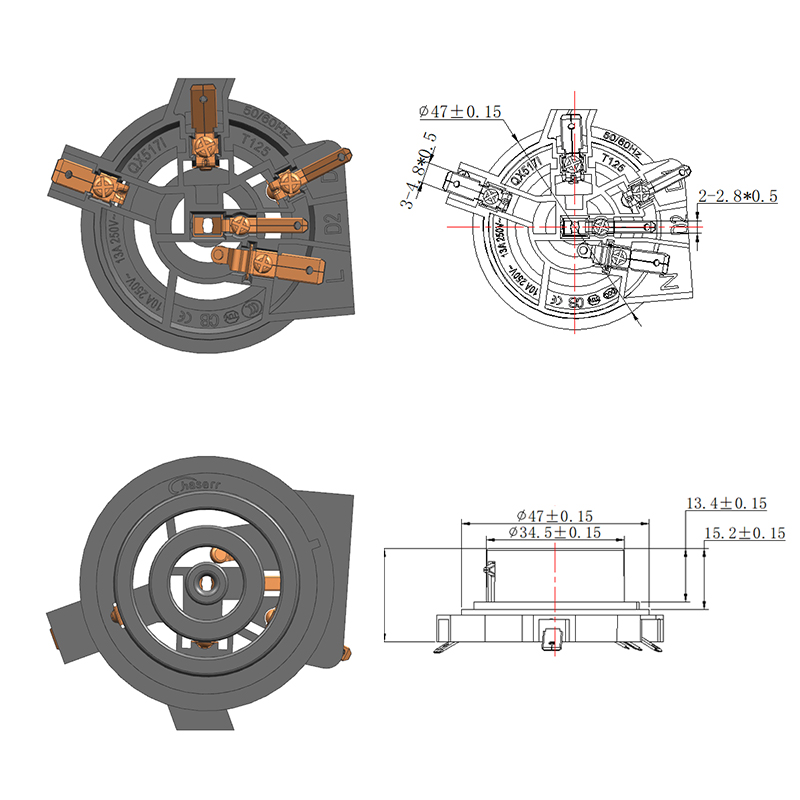

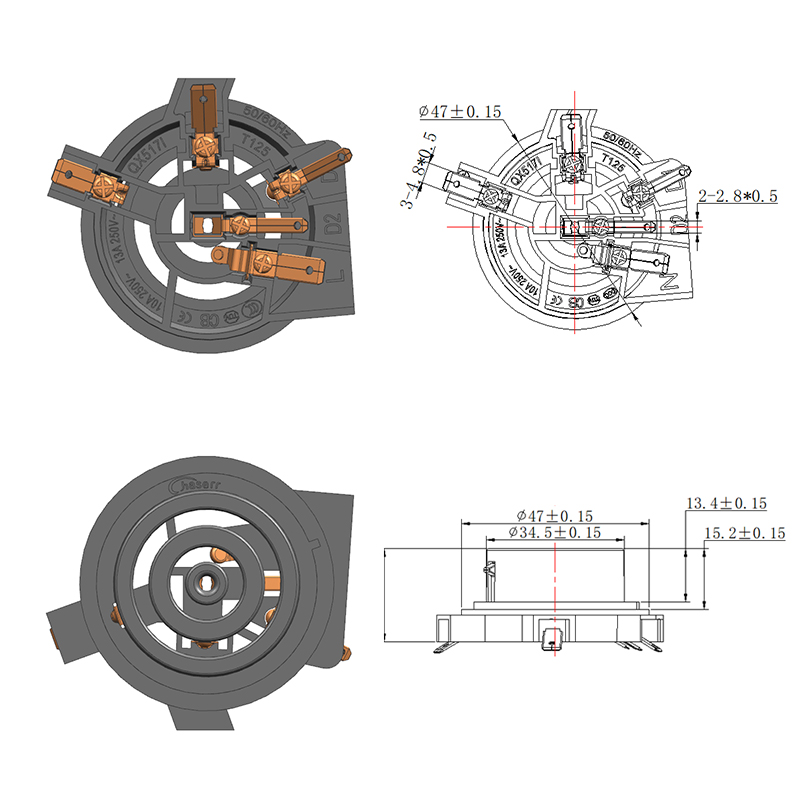

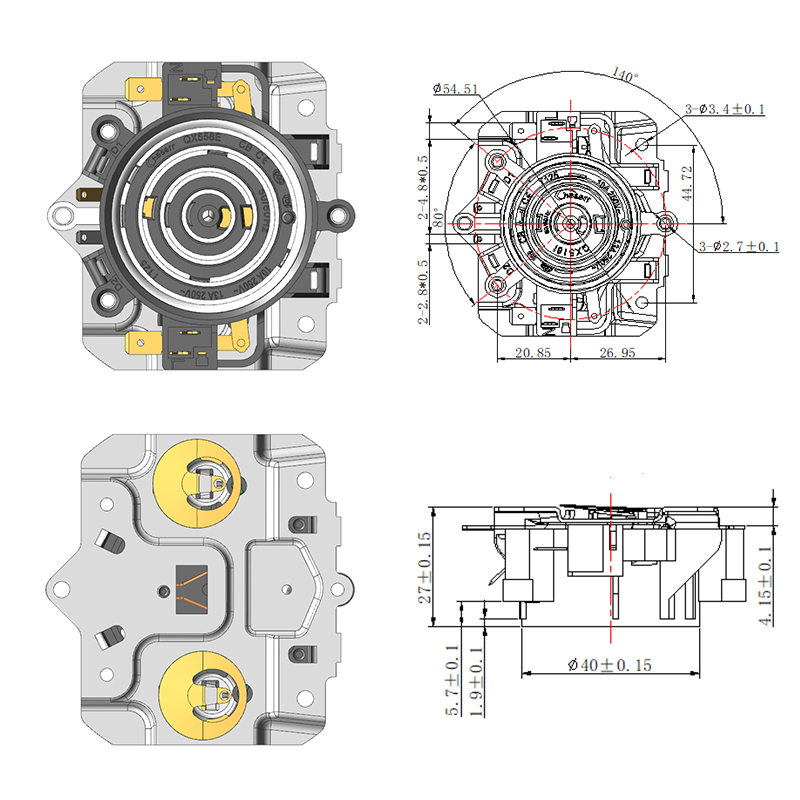

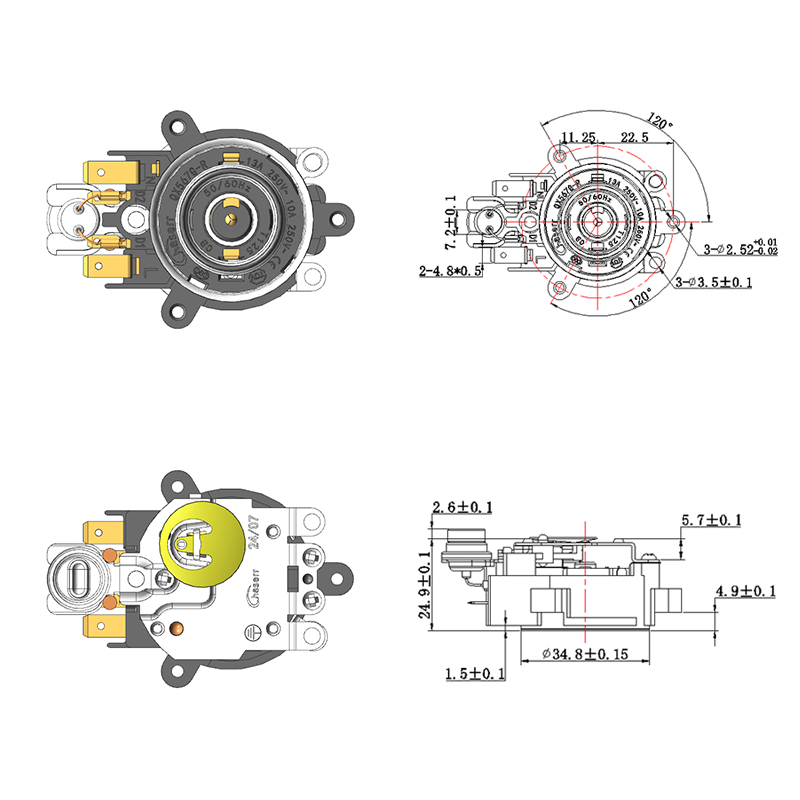

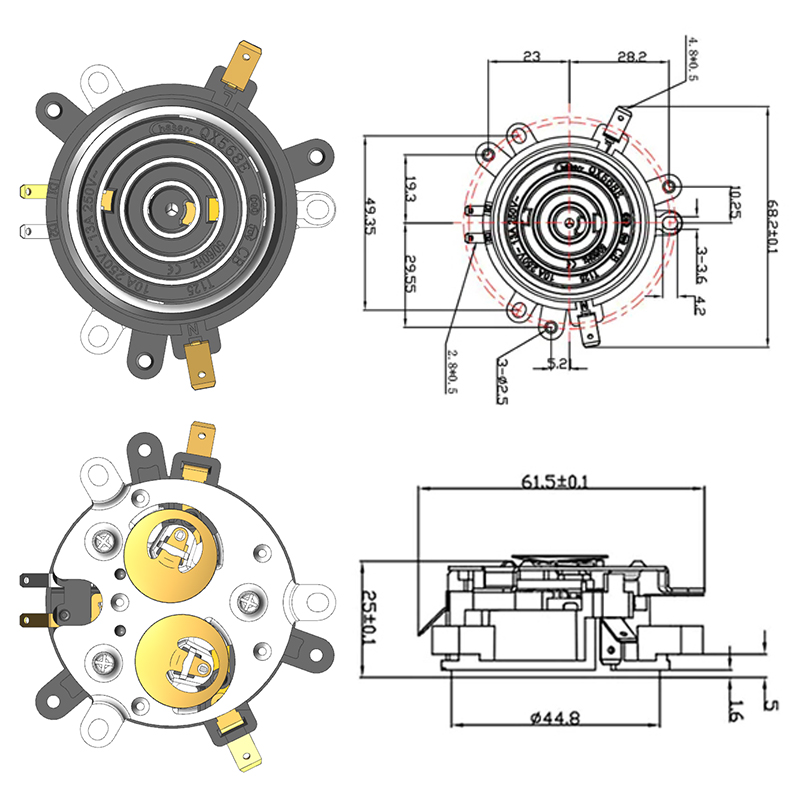

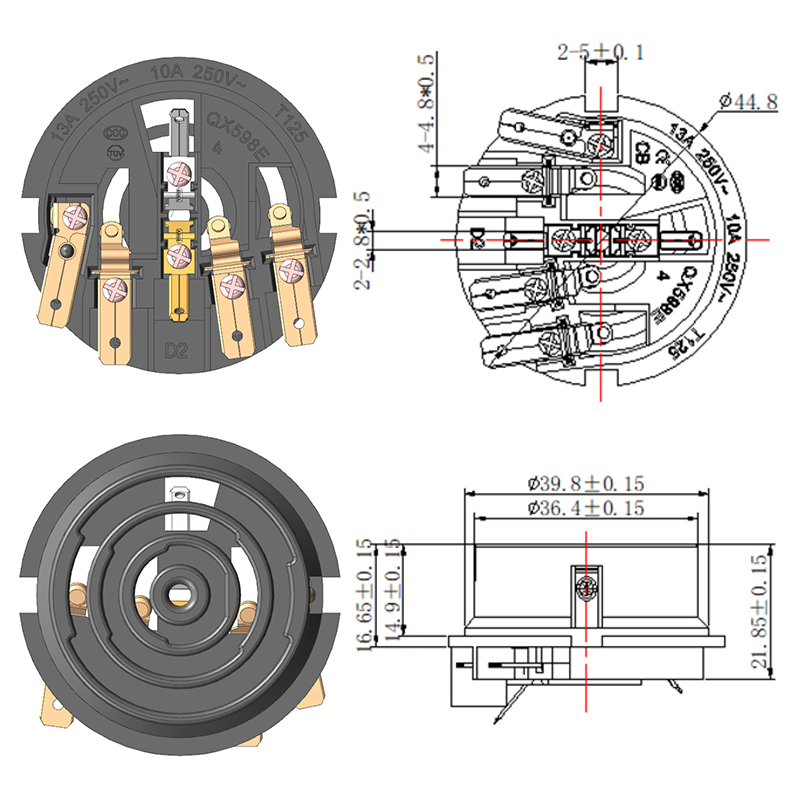

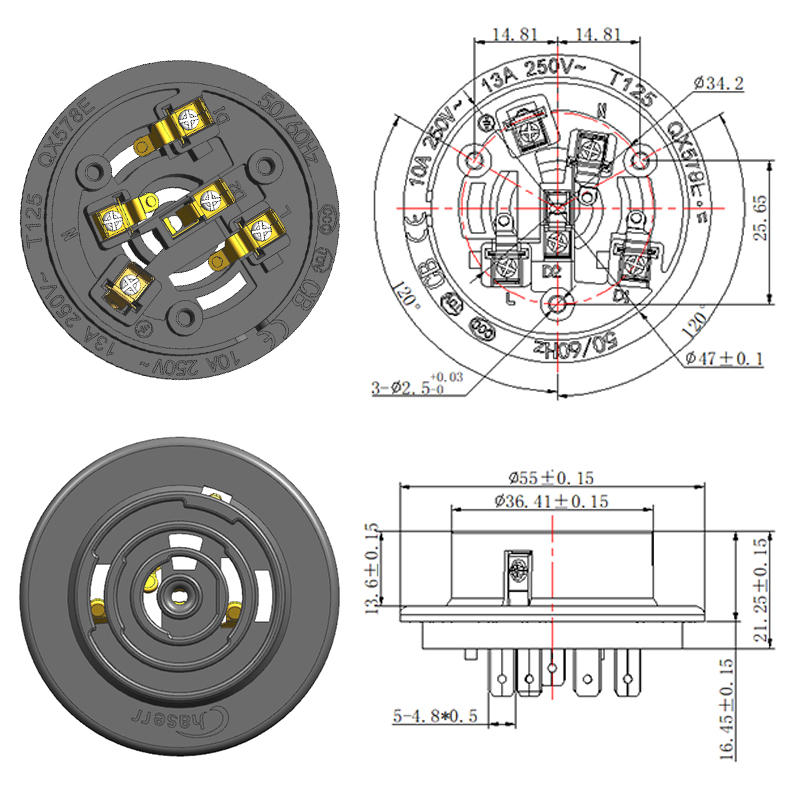

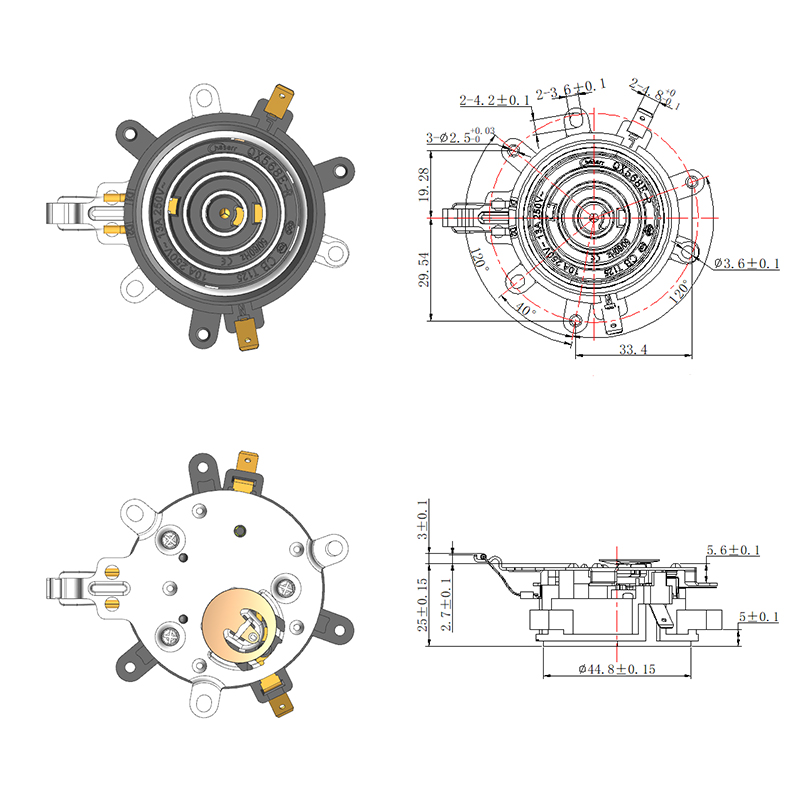

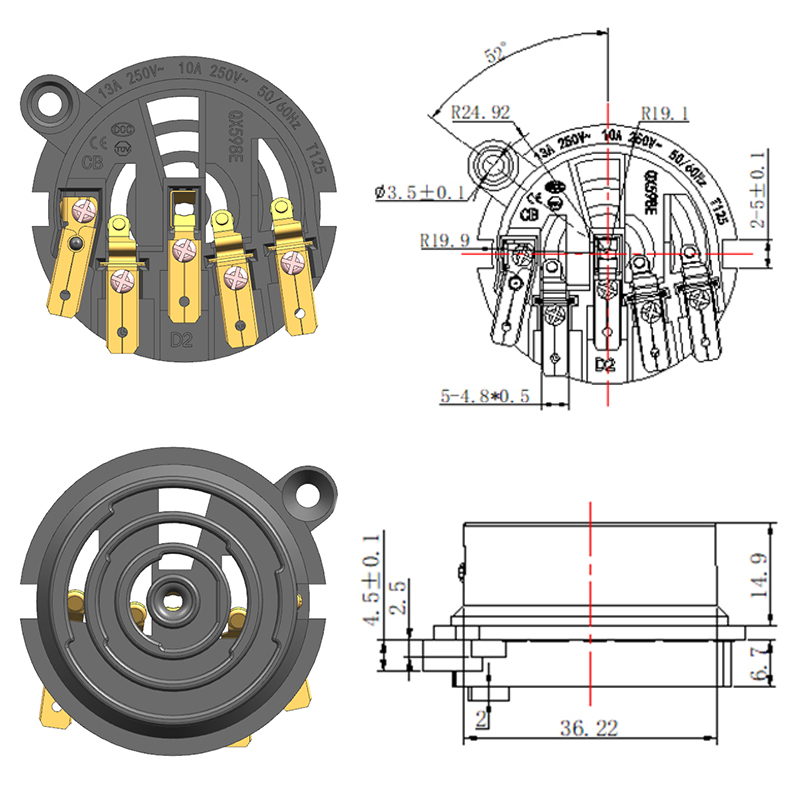

- Automatic Three Ring Kettle Coupler

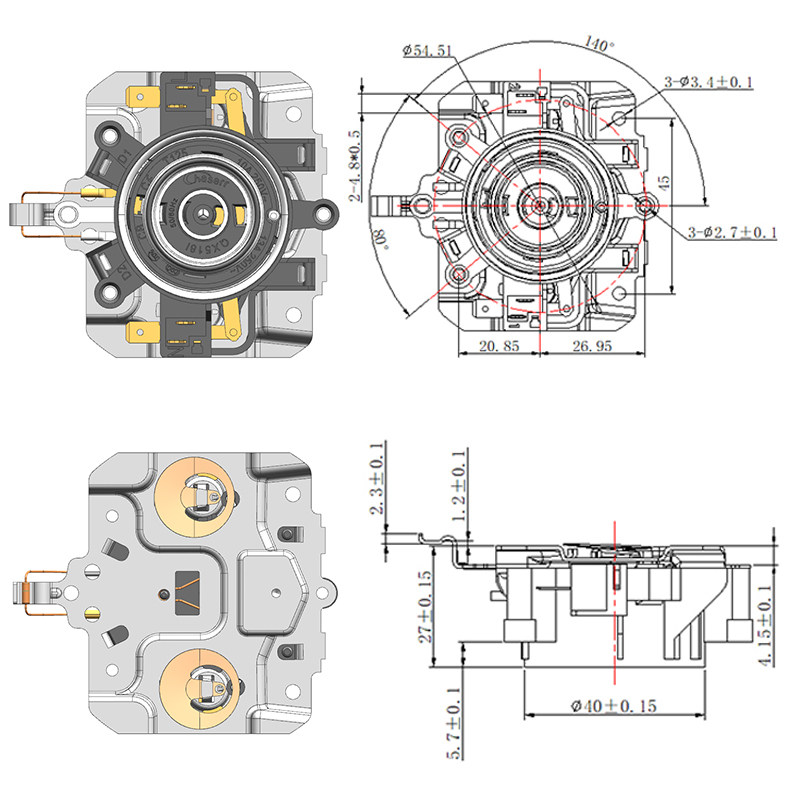

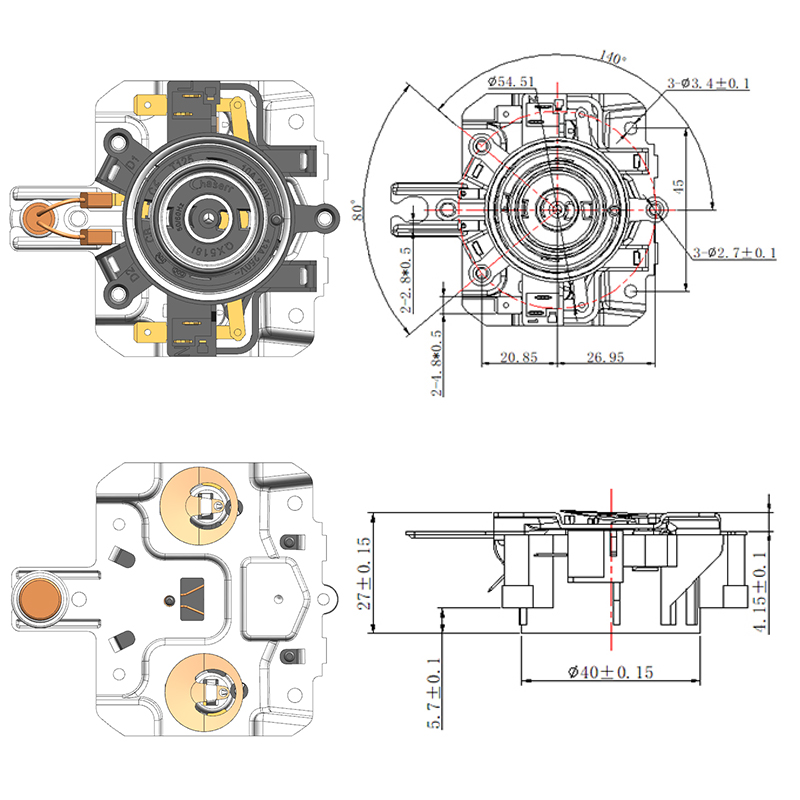

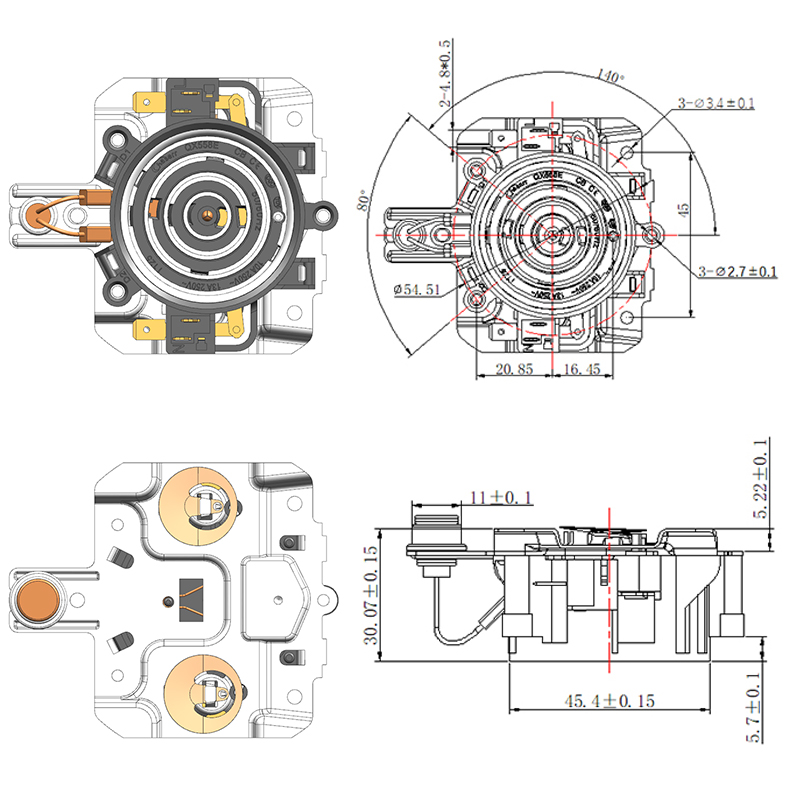

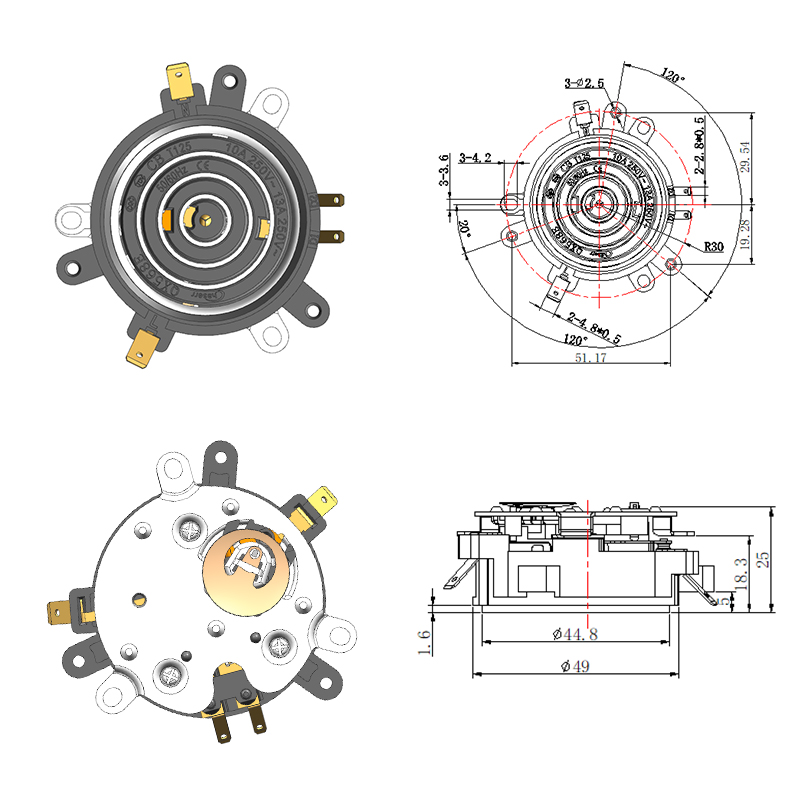

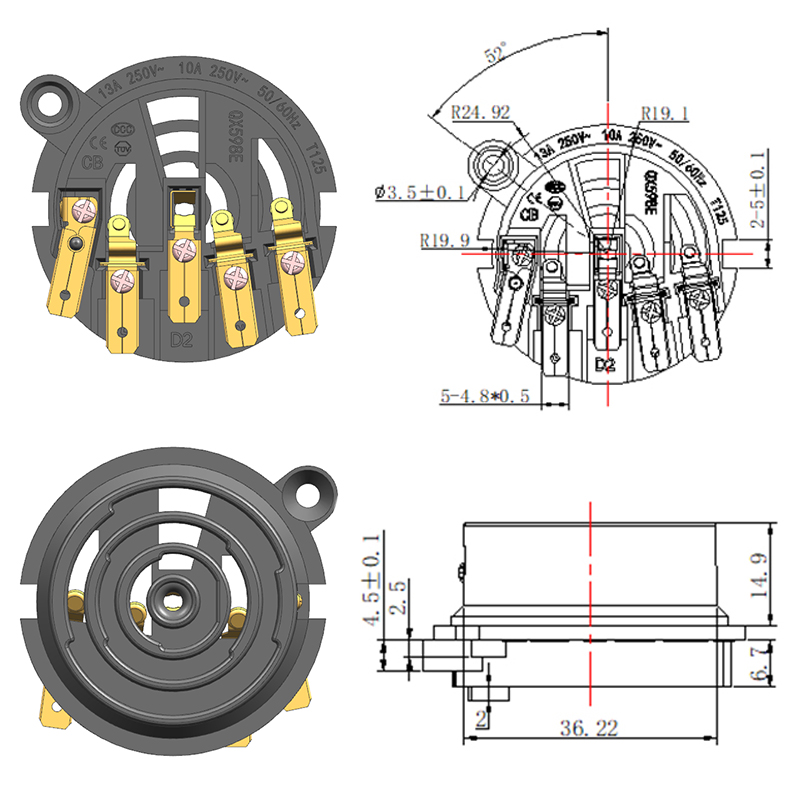

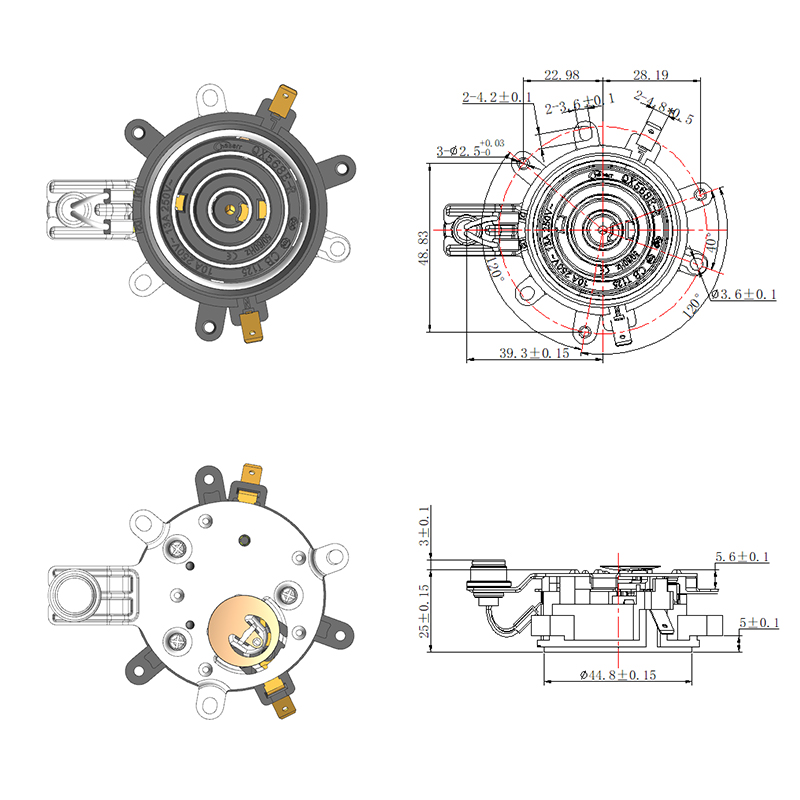

- Multifunction Automatic Smart Kettle Thermostat Coupler

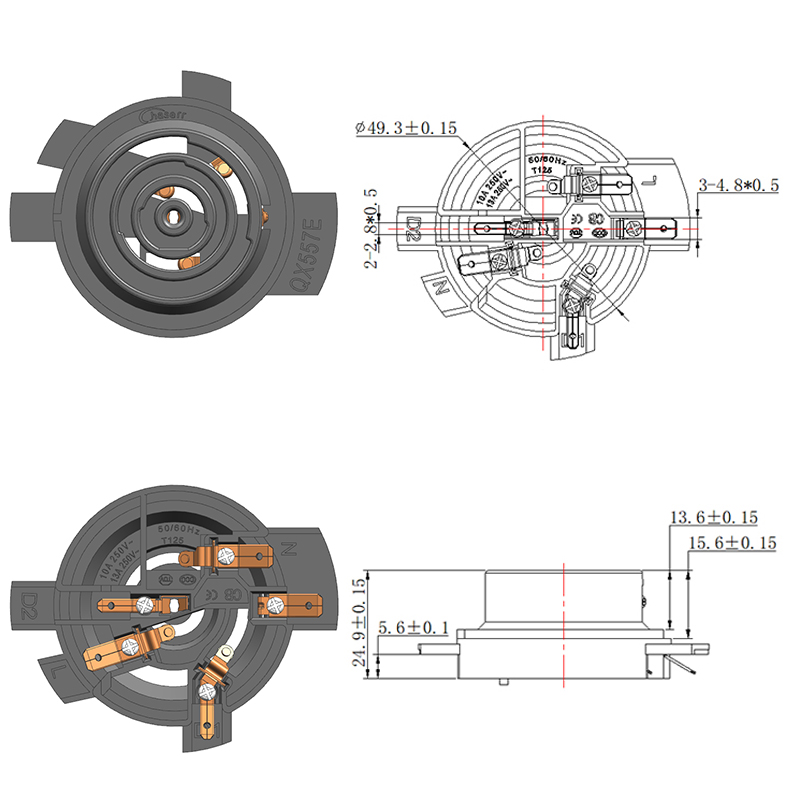

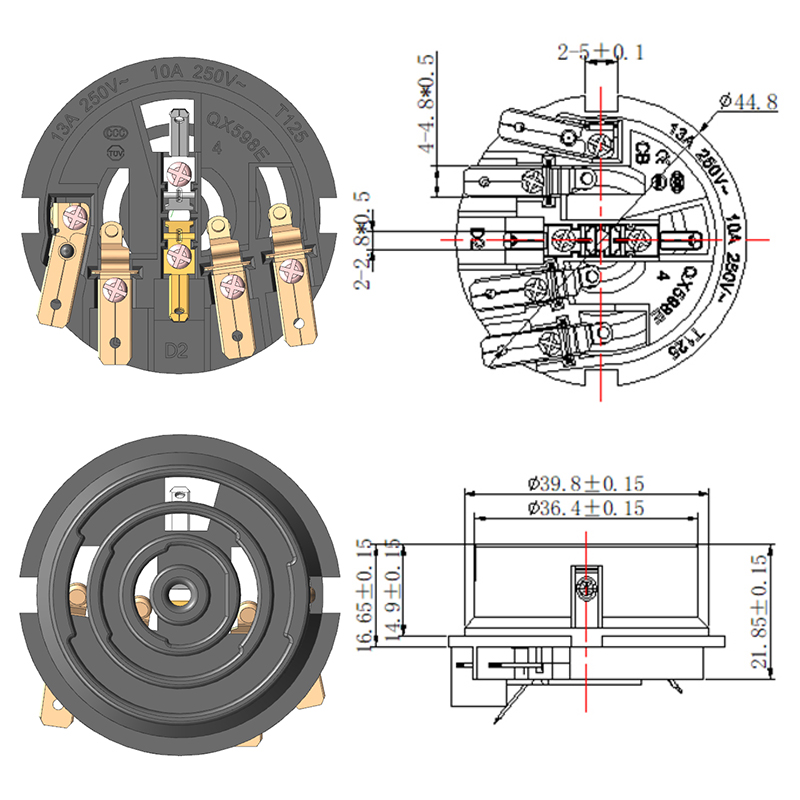

- Automatic Water Supply Smart Kettle Thermostat Coupler

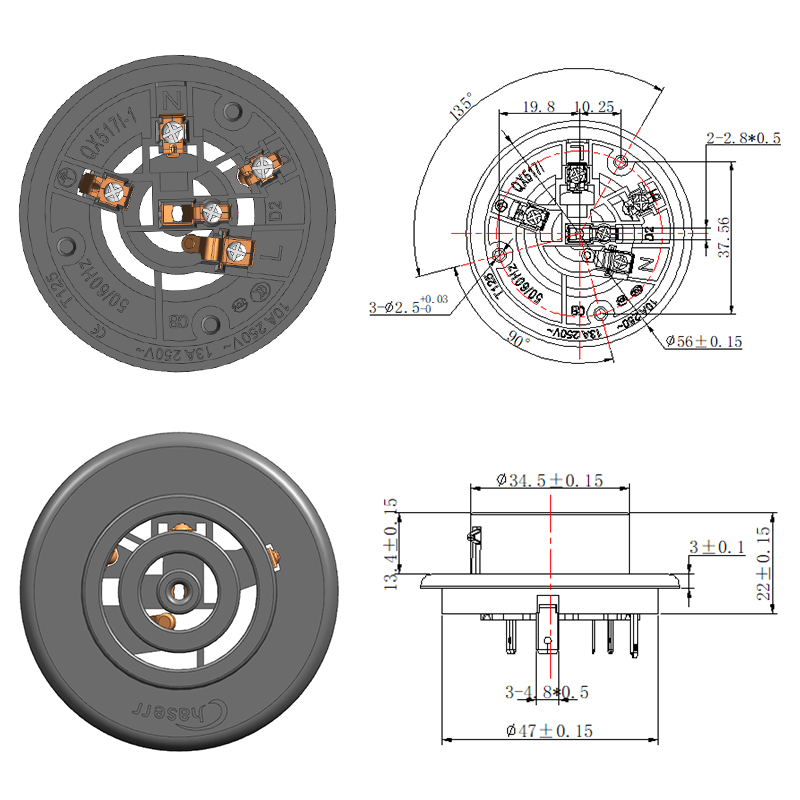

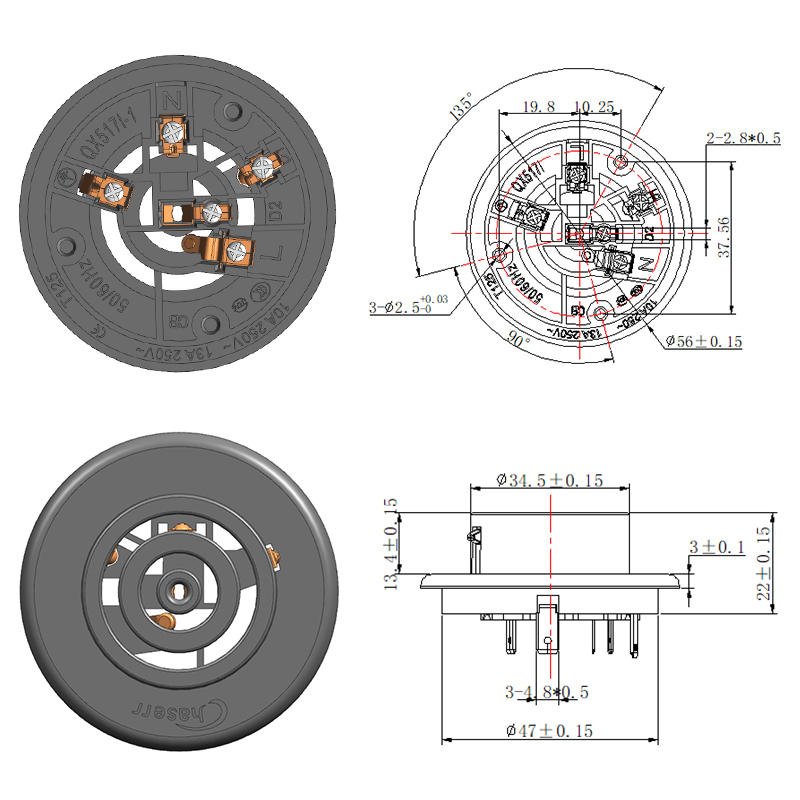

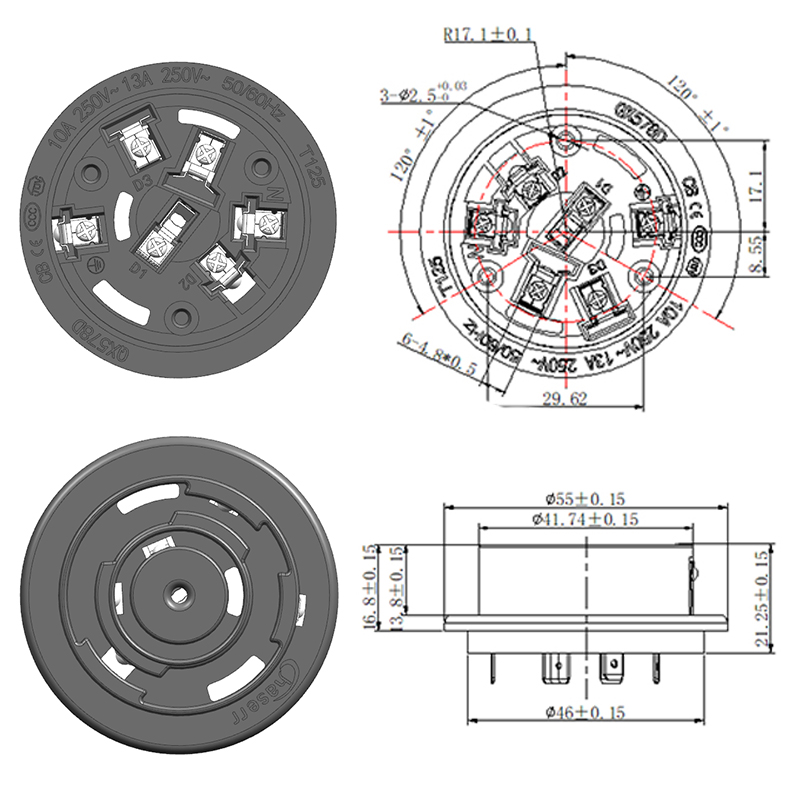

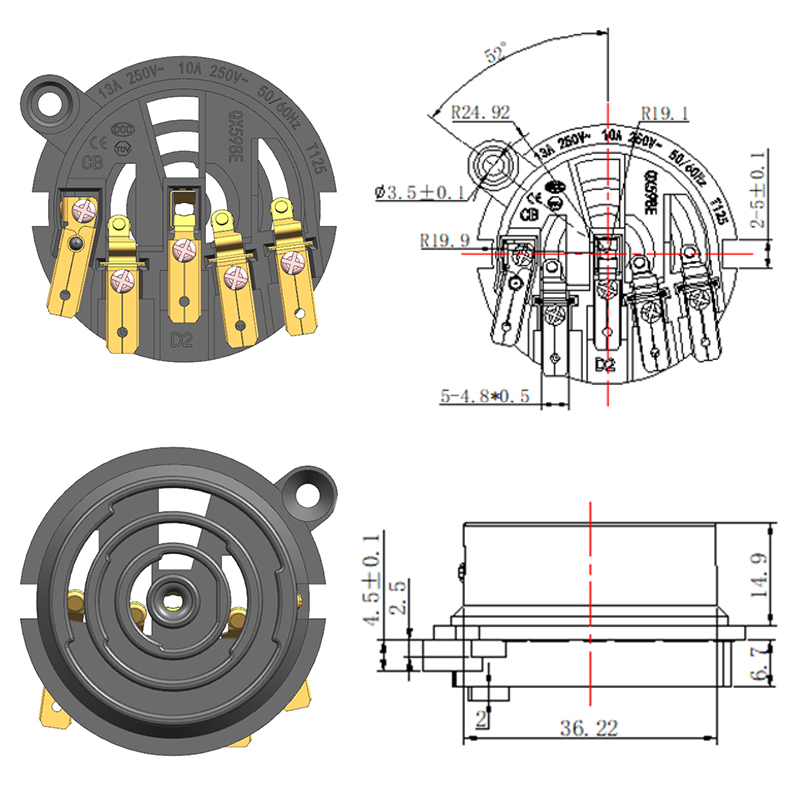

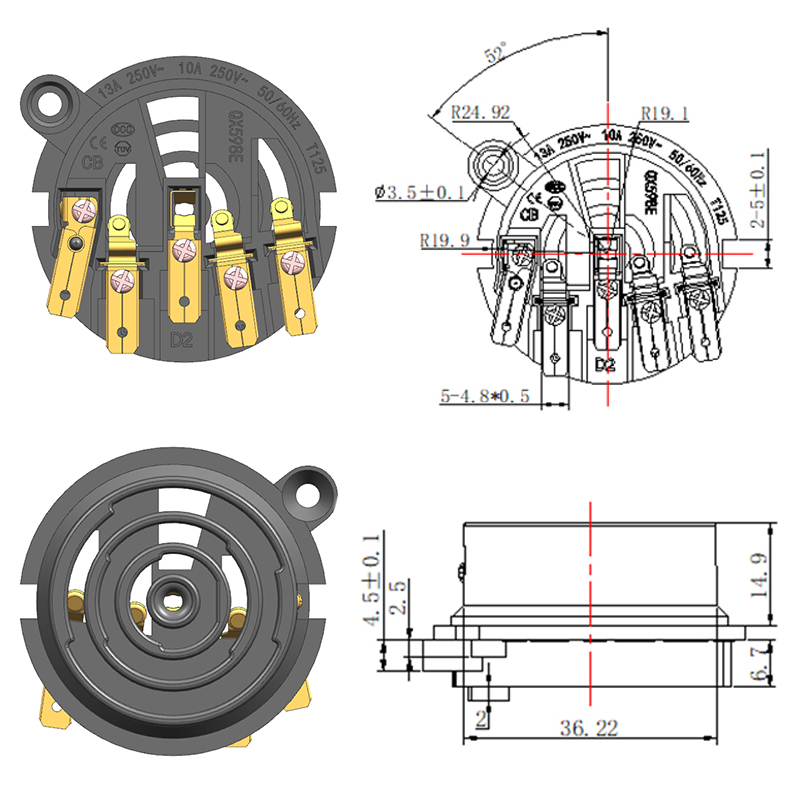

- Automatic Three Ring Kettle Coupler Base

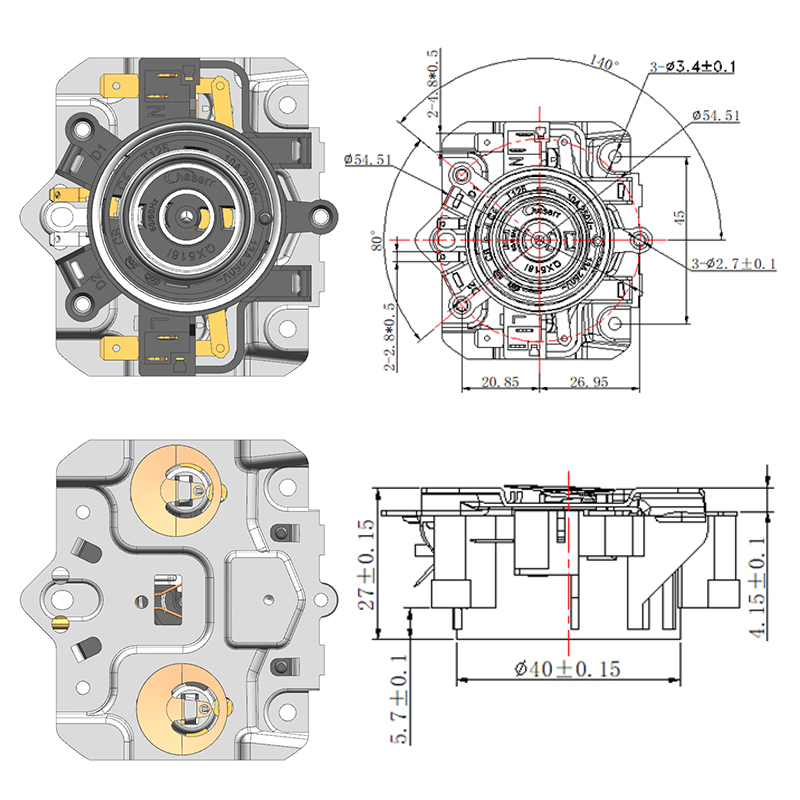

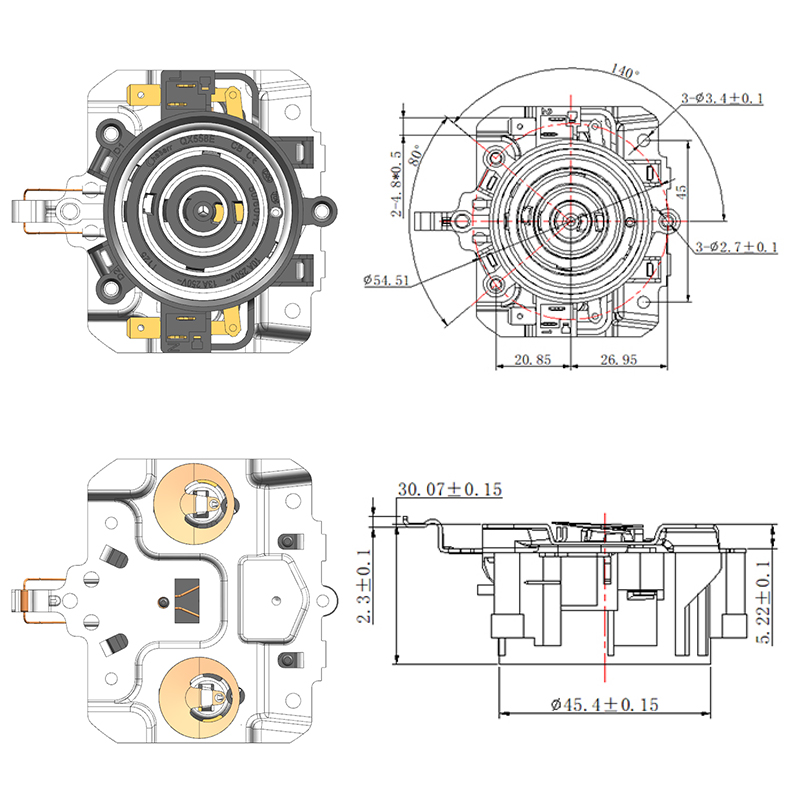

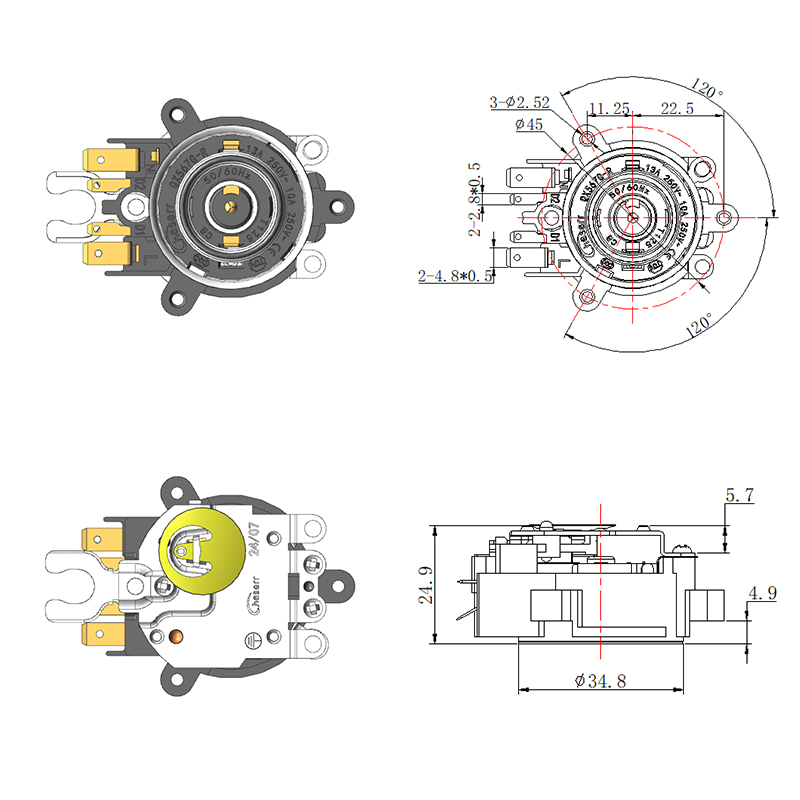

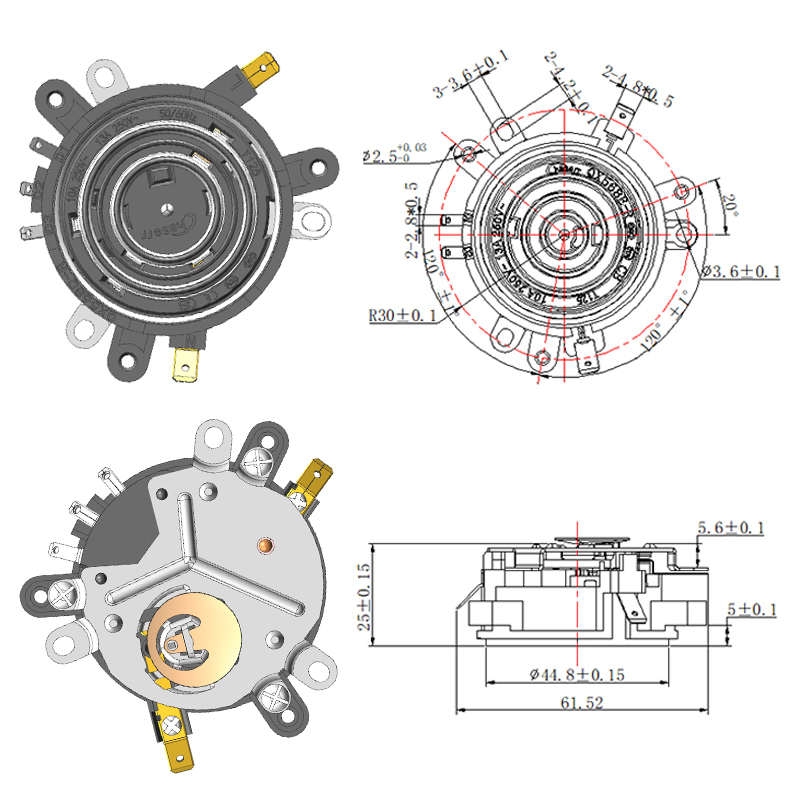

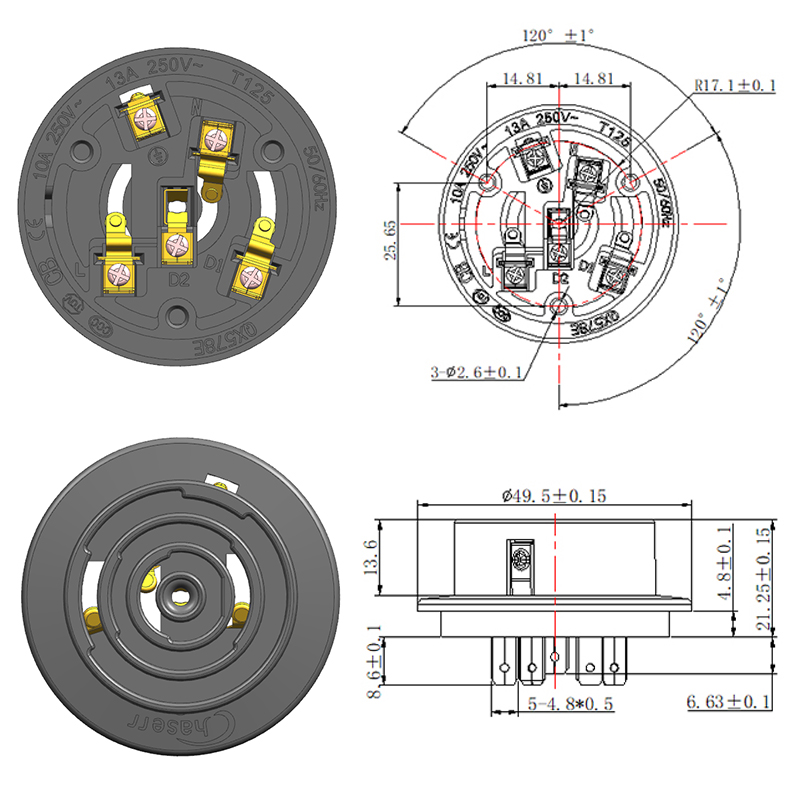

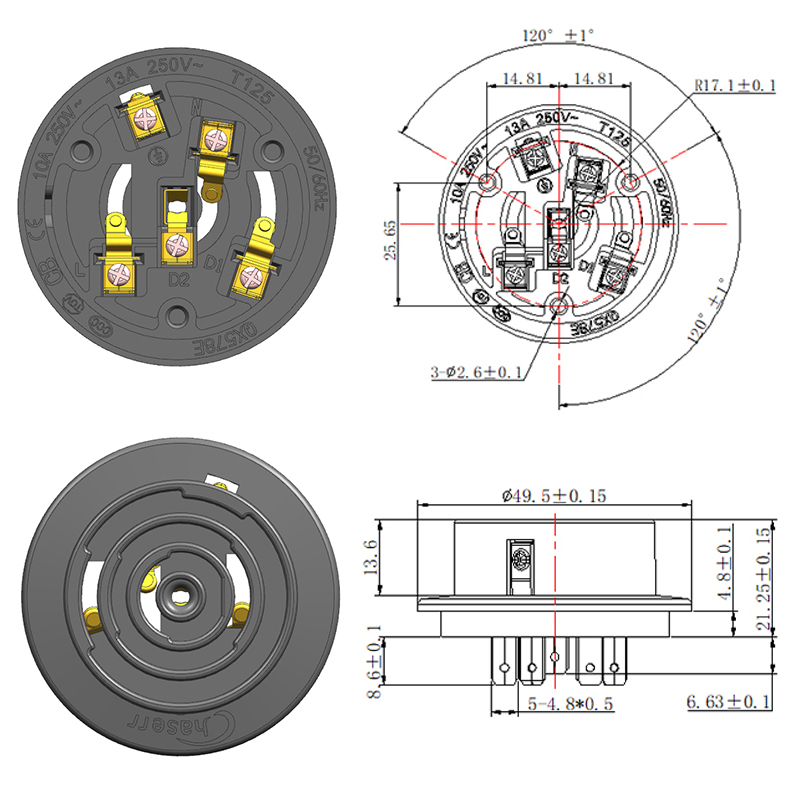

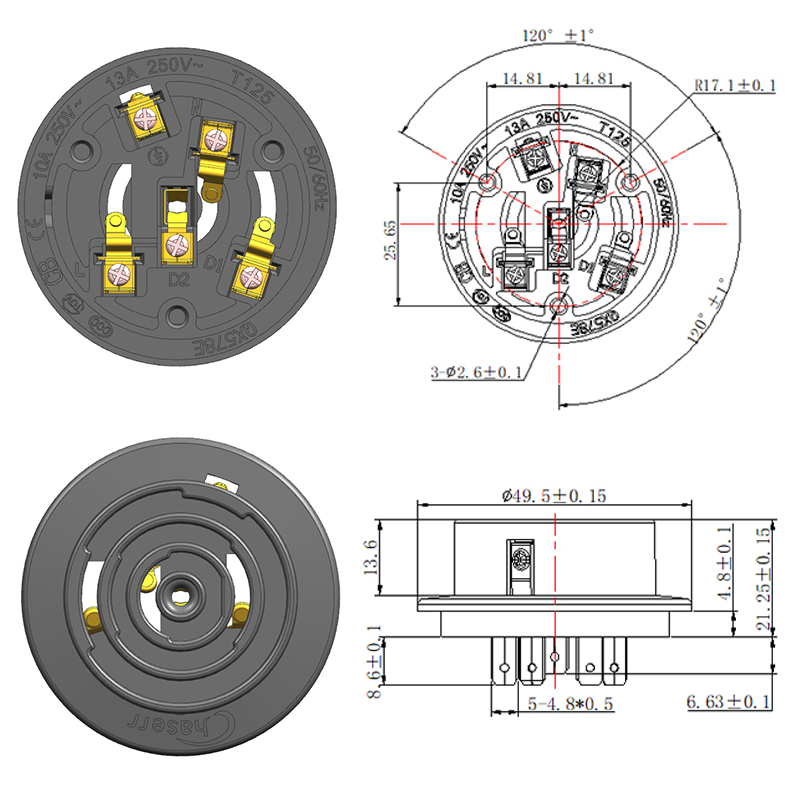

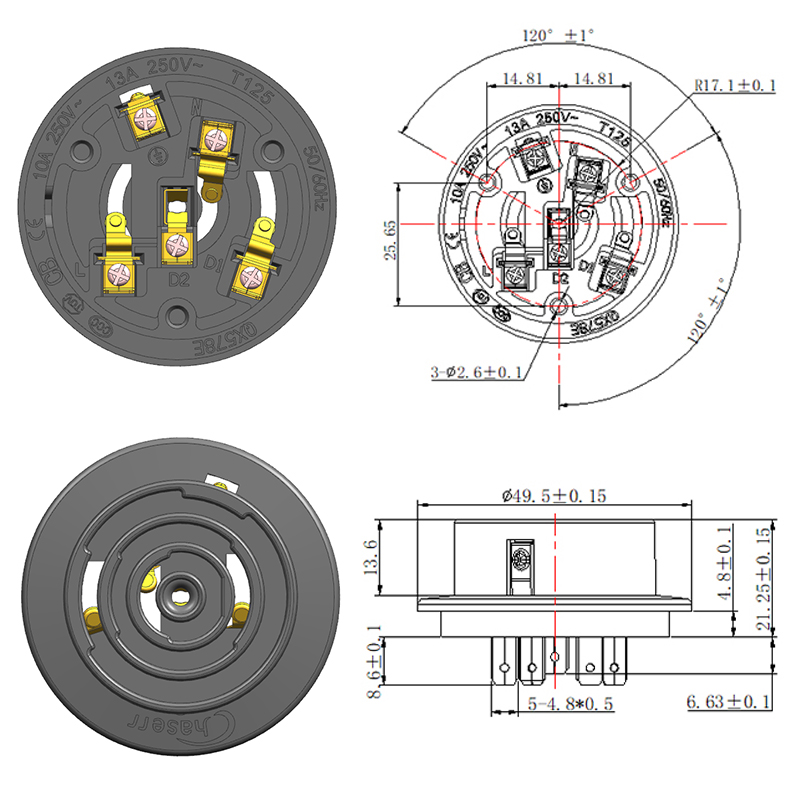

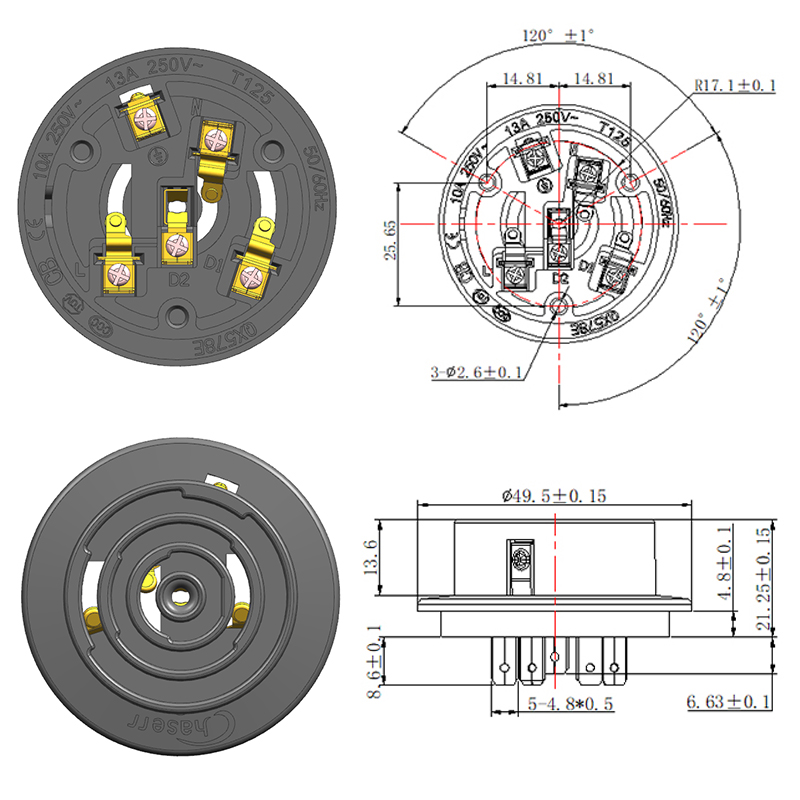

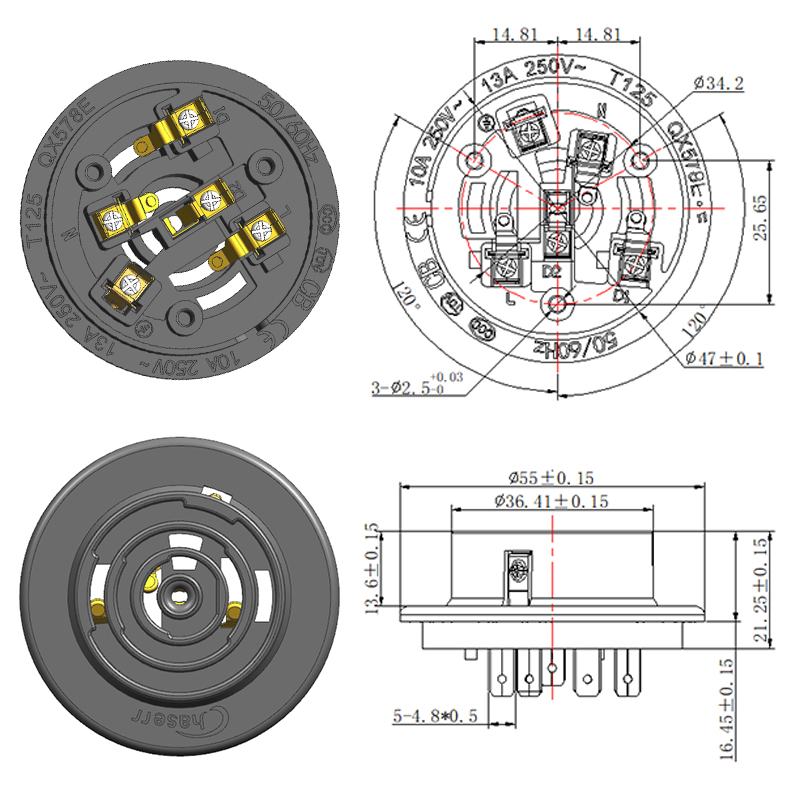

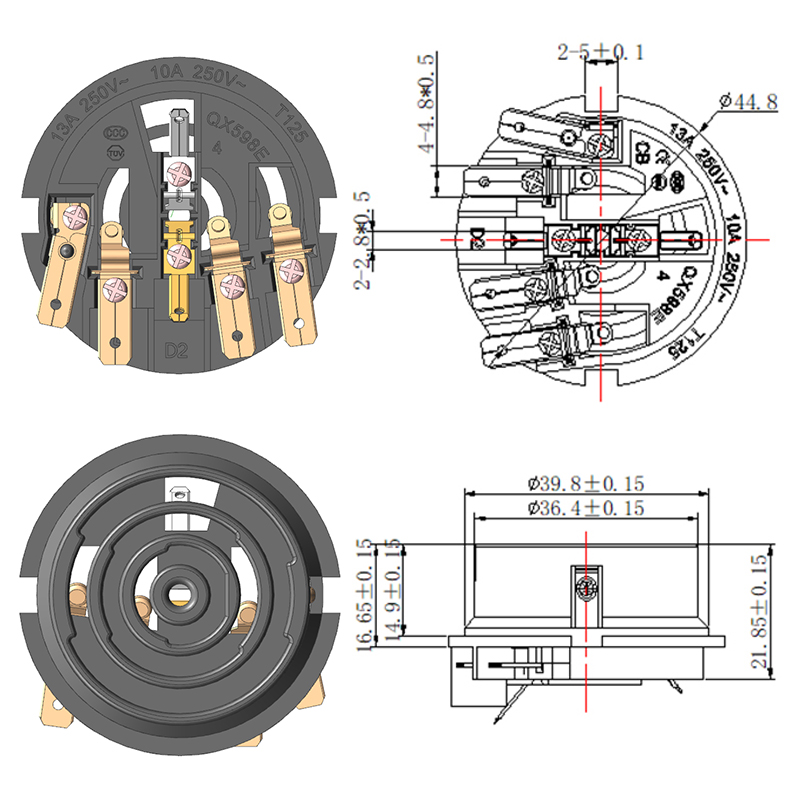

- Multifunction Automatic Smart Kettle Thermostat Coupler Base

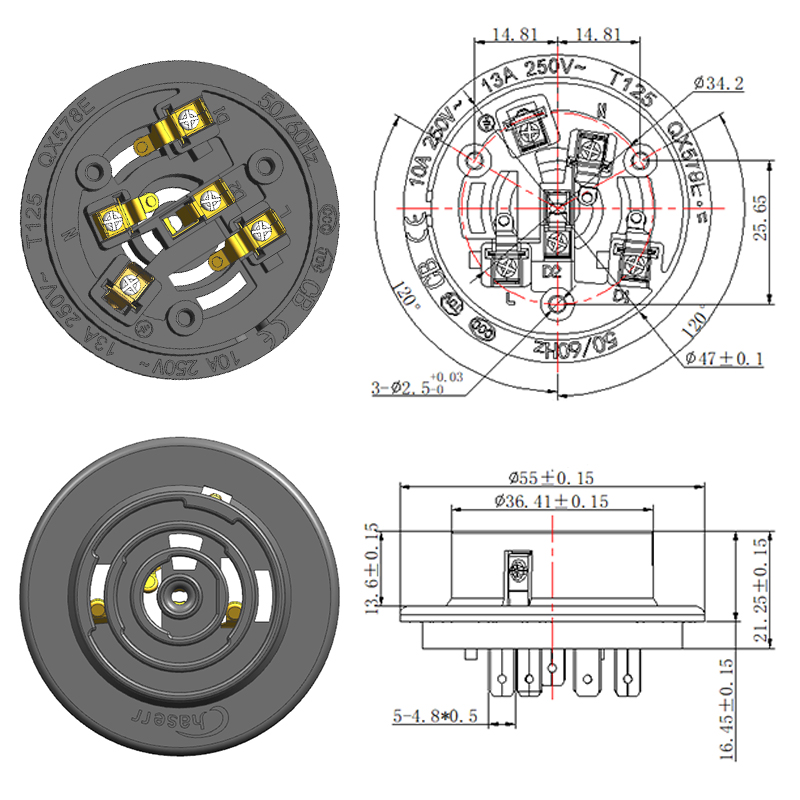

- Automatic Water Supply Smart Kettle Thermostat Coupler Base

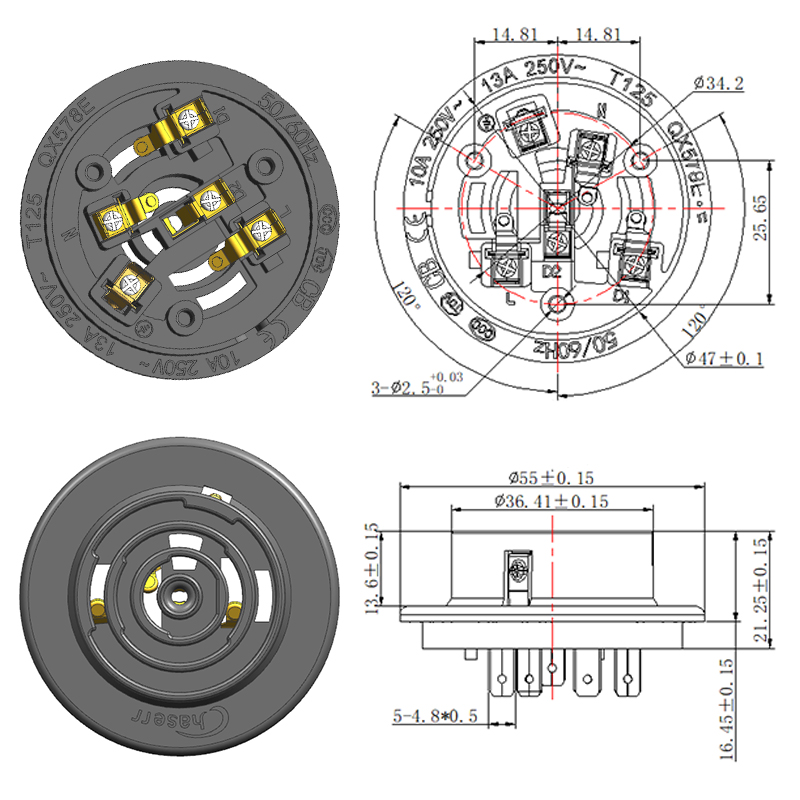

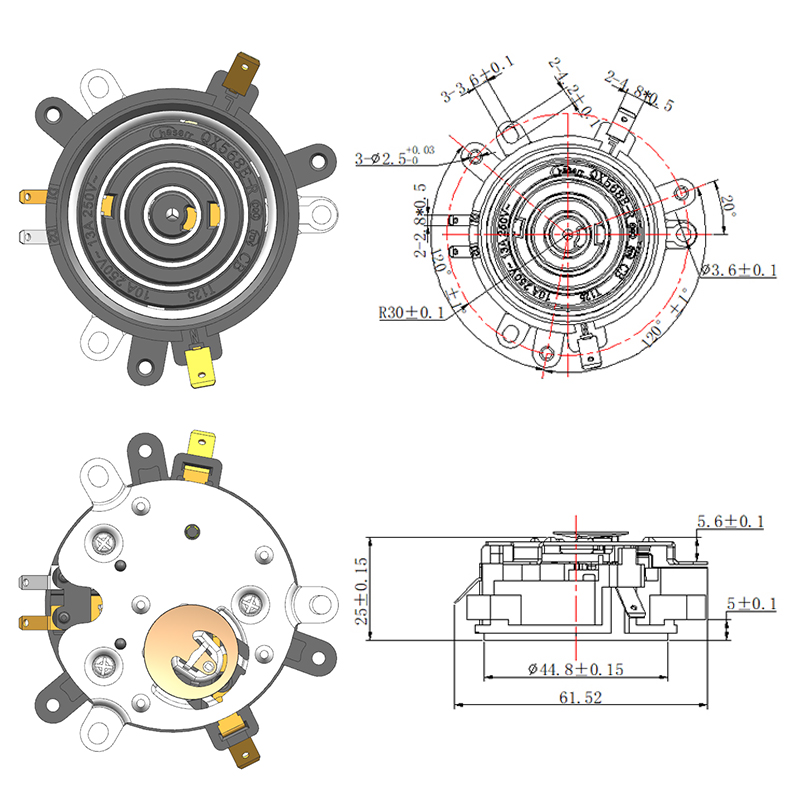

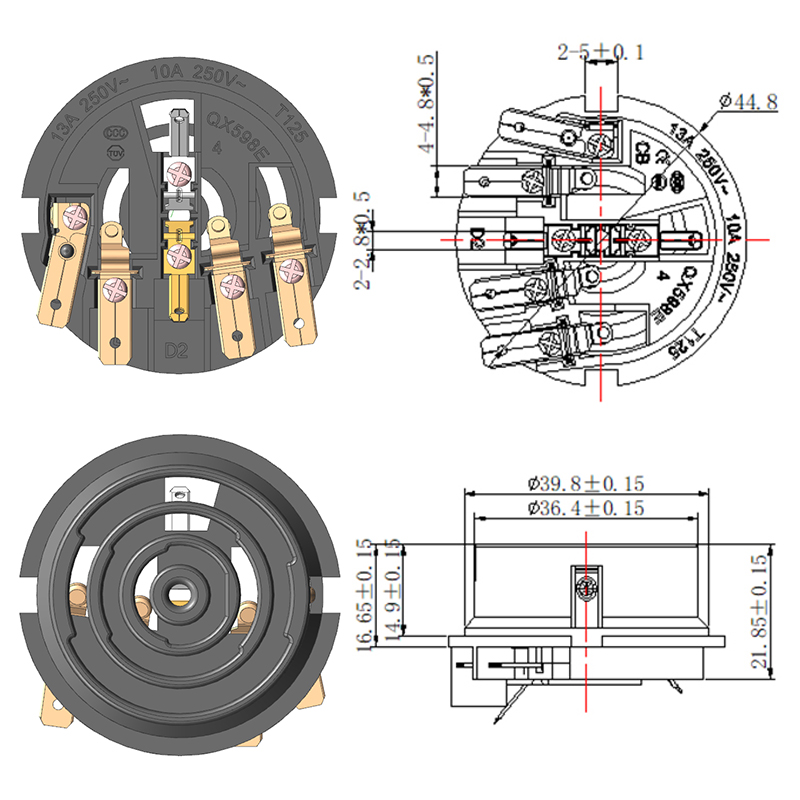

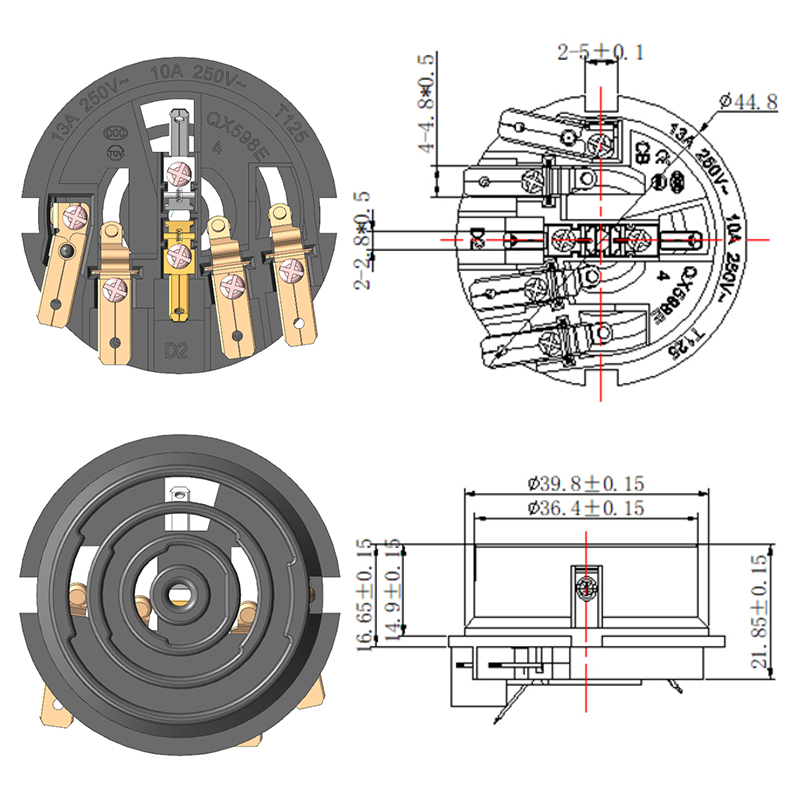

Automatic Smart Kettle Thermostat Coupler Base

-

×

-

×

-

×

-

×

-

×

-

×

-

×

-

×

-

×

-

×

-

×

-

×

The Multifunction Automatic Smart Kettle Thermostat Coupler Base is a key component designed to control, connect, and manage the heating process of electric kettles.

Applications of the Multifunction Automatic Smart Kettle Thermostat Coupler Base

Smart Electric Kettles

Essential for kettles used in homes with smart home integration.Enables features like scheduled boiling, temperature presets, and remote activation.

Temperature-Sensitive Beverage Preparation

Ideal for kettles used to prepare tea, coffee, or baby formula requiring specific water temperatures.Assists in delivering consistent results without manual temperature checks.

The Multifunction Automatic Smart Kettle Thermostat Coupler Base is a thoughtfully engineered component that blends intelligent control, safety features, and user convenience.

About Us

Wenzhou Qianxun Electrical Technology Co., Ltd. a professional China Multifunction Automatic Smart Kettle Thermostat Coupler Base manufacturer and wholesale Multifunction Automatic Smart Kettle Thermostat Coupler Base factory, is located in Tiancheng Industrial Zone, Yueqing City, Zhejiang Province. Since 2014, we have been dedicated to the field of thermostats. Guided by the value of "becoming a well-known innovator and manufacturer in the thermostat industry," we have been striving for progress and have now become the industry benchmark. As a reliable domestic manufacturer of Multifunction Automatic Smart Kettle Thermostat Coupler Base, Qianxun Electrical has cooperated with many enterprises at home and abroad, committed to providing customers with professional thermostat design, research and development, production, and sales services.

Qianxun Electrical possesses a professional R&D team and testing equipment. By integrating advanced design concepts and methods, we can now present to customers a variety of high-reliability, cost-effective patented products, including the patented Springwater Bottom Thermostats(six/five-core), adjustable thermostats, positive pressure thermostats, waterproof five-core thermostats, and steam switches, among other series of products.

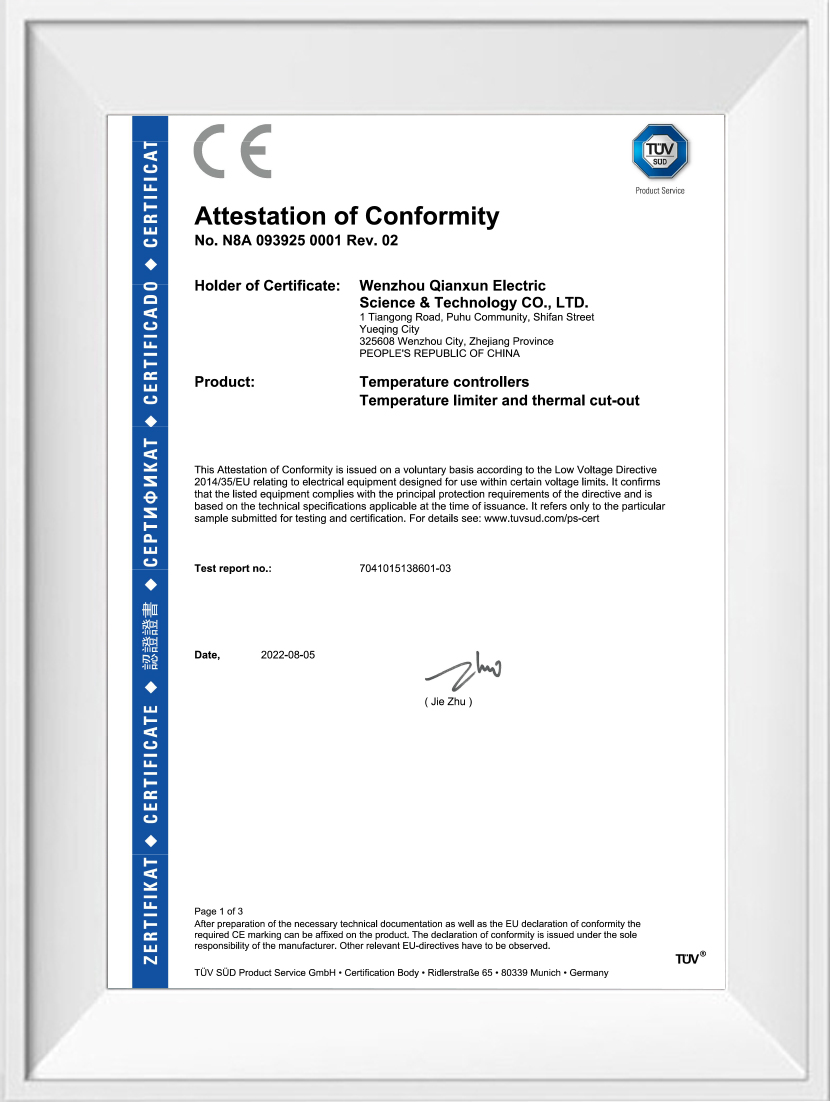

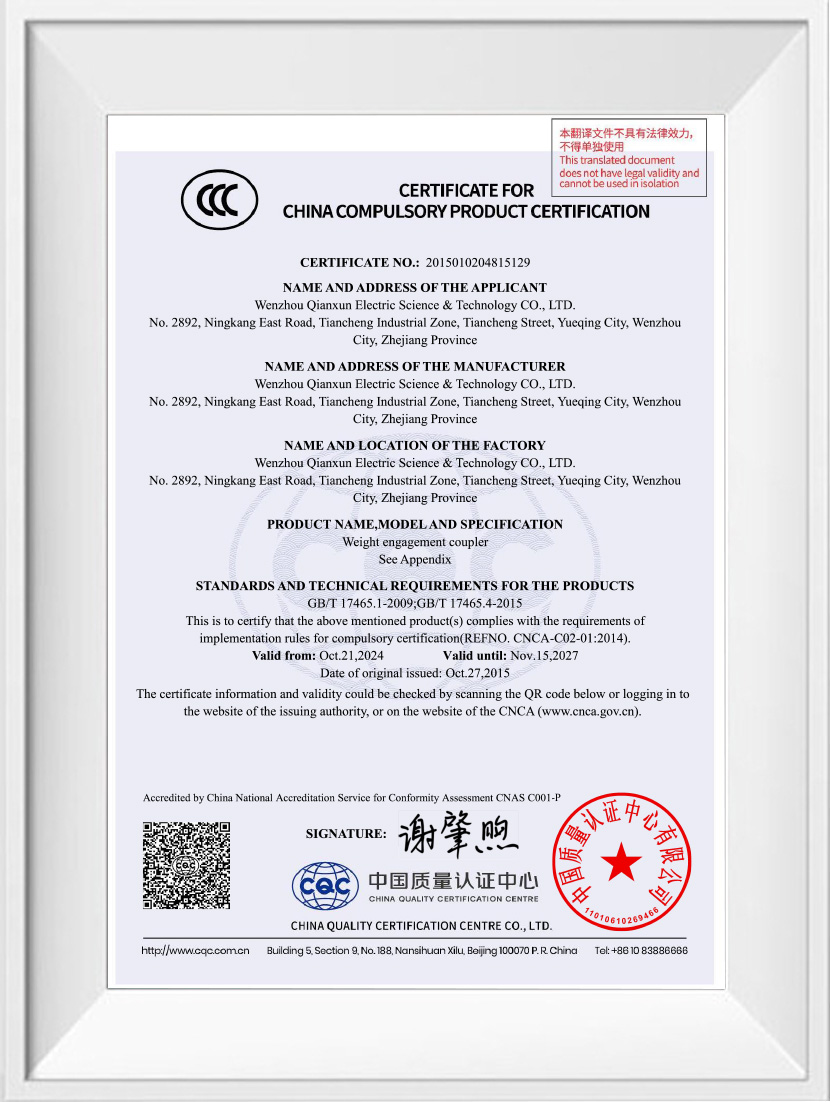

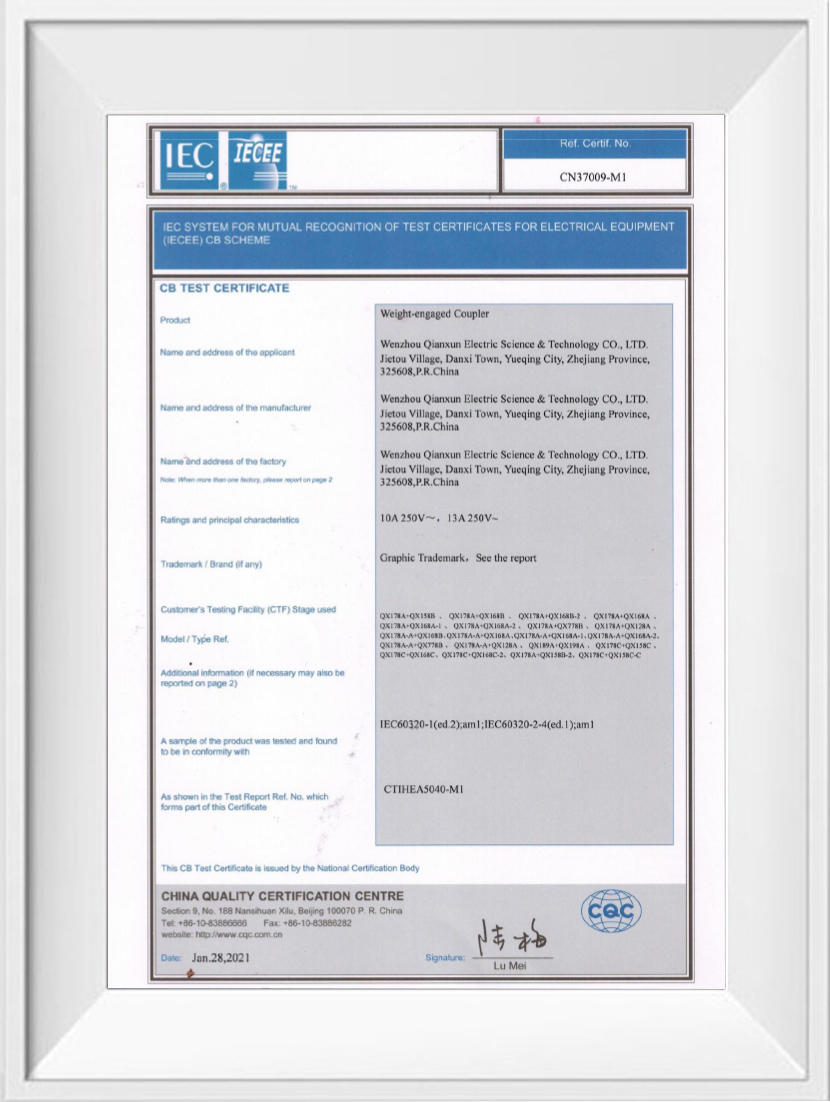

Currently, Qianxun Electrical's products have obtained the national CCC certification and the EU CE certification issued by the German TUV laboratory. Simultaneously, due to its profound technical accumulation, Qianxun Electrical is also fully capable of customizing non-standard products for use in more stringent environments and acquiring certifications such as CQC and CB for these products. Resolving customers' problems with its own technical strength is an unwavering pursuit for Qianxun Electrical.

As a reliable Multifunction Automatic Smart Kettle Thermostat Coupler Base supplier to a wide range of customers, Wenzhou Qianxun Electrical Technology Co., Ltd. exercises stringent control over the manufacturing of its products. The professional and highly skilled quality control team performs rigorous quality checks at every small detail, from research and development, production, to the final dispatch. The material control team is responsible for supply chain management, implementing efficient procurement, storage, and distribution strategies to ensure quick product delivery. The industrialization team is dedicated to intelligent manufacturing, providing a strong guarantee for the efficiency of the production site and the stability of the manufacturing processes.

Certificates

News Center

-

Industry News 2026-01-27

Introduction to Multi-Layered Kettle Safety The Anti-Drying Kettle Thermostat is a crucial safety component in modern el...

View More -

Industry News 2026-01-23

Introduction to Dry Boil Protection The Dry Boil Protection Kettle Part Coupler is an essential safety component in mode...

View More -

Industry News 2026-01-16

Importance of Accurate Coupling The Kettle Thermostat Coupler serves as a critical interface between the kettle’s heatin...

View More

Contact us now

Multifunction Automatic Smart Kettle Thermostat Coupler Base Industry Knowledge Extension

On a fundamental level, this coupler base provides durable electrical continuity for high current flow. However, its noteworthy value lies in its ability to integrate auxiliary signaling capabilities—often implemented as a dedicated ring or pin—for smart features such as water level detection, temperature feedback loops, LED indicators, or even microcontroller-based functionality.

From a materials and manufacturing standpoint, the housing is molded from high-performance glass-filled nylon or phenolic resin, materials chosen for their good resistance to heat, moisture, and mechanical wear. The molding process incorporates snap-fit hooks, keying tabs, and alignment guides, enabling automated assembly lines to seat the base quickly and accurately without imparting undue force on internal conductors. At the same time, the internal cavity is engineered with labyrinth seals or weep channels to effectively divert steam and moisture away from conductive paths, thus preserving dielectric integrity in compliance with IEC 60335-1 and UL 376 standards. Ensuring moisture protection is critical in kettle applications, where steam condensation is relentless, and even a tiny conductive path due to water vapor could compromise both performance and safety; Qianxun's solution lies in proven water ingress mitigation built directly into the base's design.

The inclusion of the smart or auxiliary ring elevates the coupler base beyond traditional connector roles, as it allows kettle manufacturers to integrate additional sensors or indicators with minimal extra assembly. For example, this contact can tie into a low-voltage detection loop so that if the kettle is dry or if a lid is not fully seated, power is prevented from flowing. It may also trigger a keep-warm mode or notify an app via connected control modules, supporting product differentiation in the rapidly evolving smart appliance market. Qianxun further offers customization, enabling OEMs to specify plating type, terminal geometry, housing color, logo embossing, or packaging—even in OEM-scale runs—without resetting production tooling, leveraging modular manufacturing capability for brand alignment and supply chain efficiency.

Mechanically, the coupler base's spring-loaded rings maintain constant radial force against their matching kettle base contacts. This feature ensures smooth power transfer even when the kettle is lifted or placed back down, and the auxiliary ring maintains functional engagement independent of the main power rings, preserving smart feature continuity while the kettle is in use. In the assembly phase, operators and machines benefit from clear tactile feedback via audible clicks when the base is fully inserted, and automated vision systems verify insert alignment, contact geometry, and housing integrity before shipping. This automated line-level inspection is crucial for a component whose failure could result in poor heating performance, early contact pitting, or even arc tracking.

Testing processes are equally stringent. Completed bases are subjected to electrical resistance checks, insulation, and dielectric strength testing up to 1.5 kV AC, and thermal loading under full current to assess temperature rise in real use. Aging tests simulate steam exposure and tens of thousands of mating cycles to reproduce real-world kettle lifecycles and uncover any emerging failure modes. Only bases that meet Qianxun's tight quality thresholds are delivered to customers, supporting global regulatory compliance and product safety.

The smart base's modular design also delivers service advantages. In case the thermostat fails or the kettle requires repair, the base can be left in place while the thermostat or smart module is replaced, reducing waste and simplifying after-sales service. This is a deliberate choice reflecting a broader industry trend toward modular design and circular economy principles—components that can be replaced individually extend product life and reduce environmental impact.

English

English  中文简体

中文简体  Español

Español