- Bimetal Thermostat

-

Steam Kettle Thermostat Switch

-

Kettle Thermostat Coupler

- Adjustable Temperature Kettle Coulper

- Two-Piece Kettle Thermostat Coulper

- Automatic Three Ring Kettle Coupler

- Multifunction Automatic Smart Kettle Thermostat Coupler

- Automatic Water Supply Smart Kettle Thermostat Coupler

- Automatic Three Ring Kettle Coupler Base

- Multifunction Automatic Smart Kettle Thermostat Coupler Base

- Automatic Water Supply Smart Kettle Thermostat Coupler Base

Custom Three Ring Kettle Coupler Base

information to be updated

The Automatic Three Ring Kettle Coupler Base serves as a highly adaptable connector base, boasting a 360-degree rotatable design that allows for flexible use. By enabling seamless communication between the thermostat and the heating element, it ensures efficient and safe operation. It is designed to be compatible with the Three-Ring Thermostat and is mainly applied to the bottom part of kettles for boiling water. This connector is suitable for a variety of appliances, such as regular kettles, health pots, tea trays, and more. Such broad applicability makes it an indispensable component in modern electrical appliance setups.

About Us

Wenzhou Qianxun Electrical Technology Co., Ltd. a professional China Automatic Three Ring Kettle Coupler Base manufacturer and wholesale Automatic Three Ring Kettle Coupler Base factory, is located in Tiancheng Industrial Zone, Yueqing City, Zhejiang Province. Since 2014, we have been dedicated to the field of thermostats. Guided by the value of "becoming a well-known innovator and manufacturer in the thermostat industry," we have been striving for progress and have now become the industry benchmark. As a reliable domestic manufacturer of Automatic Three Ring Kettle Coupler Base, Qianxun Electrical has cooperated with many enterprises at home and abroad, committed to providing customers with professional thermostat design, research and development, production, and sales services.

Qianxun Electrical possesses a professional R&D team and testing equipment. By integrating advanced design concepts and methods, we can now present to customers a variety of high-reliability, cost-effective patented products, including the patented Springwater Bottom Thermostats(six/five-core), adjustable thermostats, positive pressure thermostats, waterproof five-core thermostats, and steam switches, among other series of products.

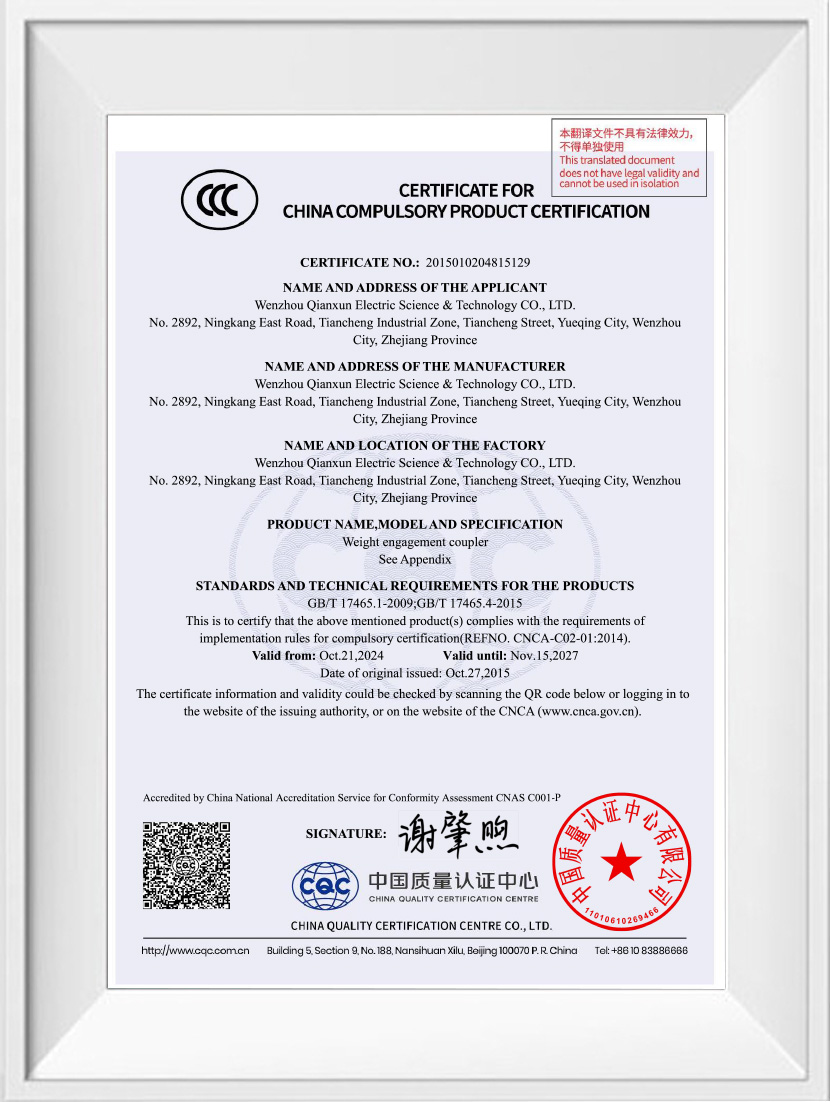

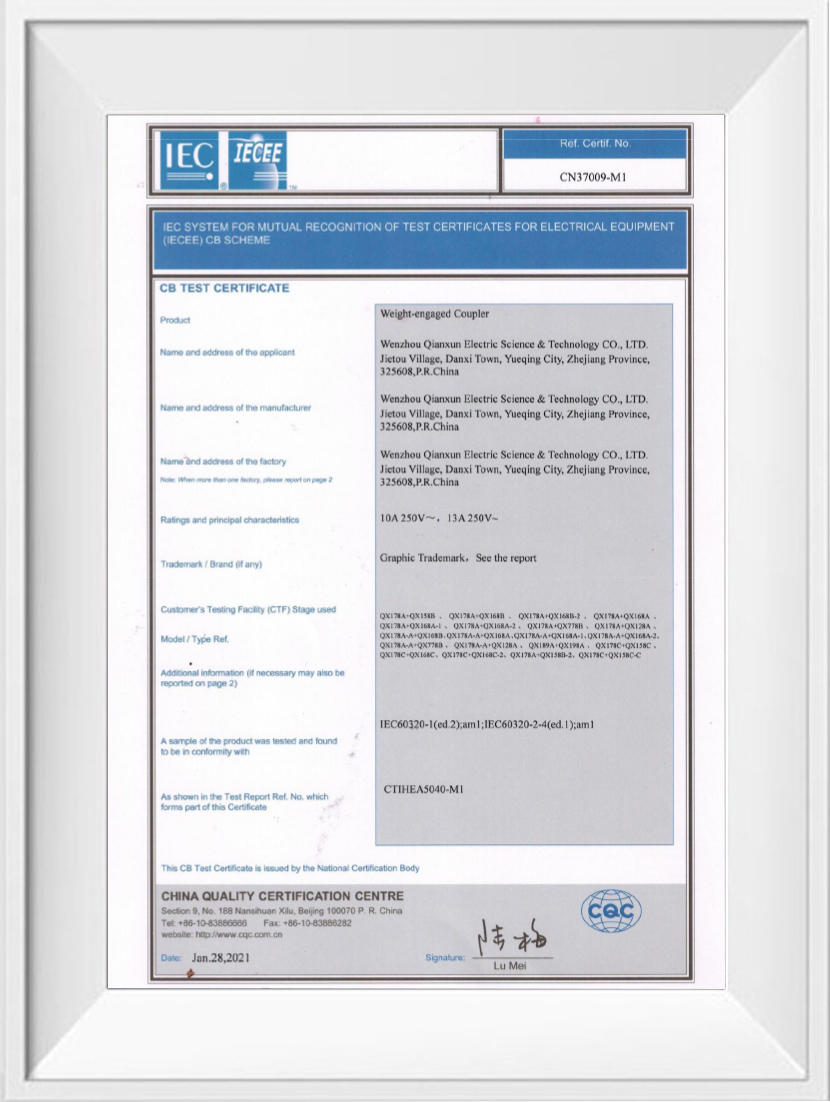

Currently, Qianxun Electrical's products have obtained the national CCC certification and the EU CE certification issued by the German TUV laboratory. Simultaneously, due to its profound technical accumulation, Qianxun Electrical is also fully capable of customizing non-standard products for use in more stringent environments and acquiring certifications such as CQC and CB for these products. Resolving customers' problems with its own technical strength is an unwavering pursuit for Qianxun Electrical.

As a reliable Automatic Three Ring Kettle Coupler Base supplier to a wide range of customers, Wenzhou Qianxun Electrical Technology Co., Ltd. exercises stringent control over the manufacturing of its products. The professional and highly skilled quality control team performs rigorous quality checks at every small detail, from research and development, production, to the final dispatch. The material control team is responsible for supply chain management, implementing efficient procurement, storage, and distribution strategies to ensure quick product delivery. The industrialization team is dedicated to intelligent manufacturing, providing a strong guarantee for the efficiency of the production site and the stability of the manufacturing processes.

Certificates

News Center

-

Industry News 2026-01-27

Introduction to Multi-Layered Kettle Safety The Anti-Drying Kettle Thermostat is a crucial safety component in modern el...

View More -

Industry News 2026-01-23

Introduction to Dry Boil Protection The Dry Boil Protection Kettle Part Coupler is an essential safety component in mode...

View More -

Industry News 2026-01-16

Importance of Accurate Coupling The Kettle Thermostat Coupler serves as a critical interface between the kettle’s heatin...

View More

Contact us now

Automatic Three Ring Kettle Coupler Base Industry Knowledge Extension

Qianxun's automatic three‑ring kettle coupler base is a finely engineered component that plays a central role in delivering reliable power transfer, safety, and versatility in modern electric kettles. From a manufacturer's standpoint, this coupler base supports three separate conductive paths—typically two power rings and an auxiliary ring designed for signal or sensing—ensuring the kettle platform can accommodate advanced features without the need for additional wiring harnesses.

The conductors within each ring are crafted using brass or copper alloys that are tin- or nickel-plated to preserve low milliohm-level contact resistance and prevent oxidation over extensive use. This precision in plating, combined with spring-loaded ring contact design, ensures consistent and smooth engagement between the kettle and its base even under frequent lifting and repositioning. In high-volume manufacturing environments, the reliability of this connection directly impacts product performance, customer satisfaction, and brand reputation, making such engineering considerations essential.

Mechanically, the coupler base housing is molded from glass-filled nylon or high-temperature phenolic resin, engineered specifically for resistance to steam, thermal cycling, and mechanical forces encountered during daily use. The molding process produces keying features and snap-fit alignment tabs, supporting accurate placement and tactile feedback during assembly. Such well-designed interfaces reduce error rates on automated lines and speed up installation, while also eliminating any residual torque on internal conductors—a critical detail for maintaining consistent electrical performance over time.

The auxiliary, third ring enables integration of supplementary circuit paths. One common use is for a control or signal line to an LED or microcontroller, enabling visual status feedback or connectivity in smart kettle designs. By embedding this functionality into the coupler, OEMs can significantly reduce manufacturing complexity and consolidate wiring pathways.

To meet electrical and safety standards, Qianxun applies rigorous quality control protocols. Metal inserts are press-fitted or ultrasonically welded into the housing, securing them firmly for long-term stability under thermal and mechanical stress. After molding, automated inspection tools check for correct insert placement, terminal geometry, and housing integrity.

Given the challenges posed by steam and condensation, internal design includes channels and seals to route moisture away from conductive parts, reducing corrosion and electrical tracking. Some variants integrate gaskets or labyrinth seals to enhance moisture protection without compromising heat dissipation. As a result, long-term dielectric integrity is maintained, and failure rates due to steam-induced degradation remain low—a critical benefit in product durability.

From a servicing perspective, the three-ring coupler base supports modular replacement. If a dishwasher or electrical failure occurs, the thermostat module can be replaced without removing the entire base, facilitating faster repairs, reducing component waste, and improving after-sales support efficiency. This modular design aligns well with sustainability goals and post-sale service expectations.

Qianxun also offers customization options: OEMs can request different ring plating finishes, terminal shapes (such as blade or pin), housing colors, logo embossing, or packaging tailored to their brand identity, even in relatively small order quantities. Such flexibility allows kettle manufacturers to differentiate their products on look, feel, and function while optimizing supply chain efficiency.

Qianxun's automatic three‑ring kettle coupler base stands as a high-quality, multipurpose component engineered for contemporary kettle platforms. Delivering reliable high-current power transfer, integrated signaling paths, moisture resilience, automated fitment design, serviceability, and global safety compliance, it enables kettle manufacturers to offer enhanced features while simplifying production and after-sales support.

information to be updated

English

English  中文简体

中文简体  Español

Español