- Bimetal Thermostat

-

Steam Kettle Thermostat Switch

-

Kettle Thermostat Coupler

- Adjustable Temperature Kettle Coulper

- Two-Piece Kettle Thermostat Coulper

- Automatic Three Ring Kettle Coupler

- Multifunction Automatic Smart Kettle Thermostat Coupler

- Automatic Water Supply Smart Kettle Thermostat Coupler

- Automatic Three Ring Kettle Coupler Base

- Multifunction Automatic Smart Kettle Thermostat Coupler Base

- Automatic Water Supply Smart Kettle Thermostat Coupler Base

Steam Iron Thermostat Manufacturer

information to be updated

The KSD301 Snap Disc Thermostat is a bimetallic snap-action thermostat widely used in electric appliances for temperature control and overheat protection. It operates by utilizing a bimetallic disc that snaps open or closed at a predetermined temperature, ensuring precise and reliable thermal regulation.

Key Features:

Snap-Action Mechanism – Rapid response to temperature changes for enhanced safety.

Bimetallic Disc – Ensures accurate and repeatable switching.

Automatic Reset or Manual Reset Options – Depending on application requirements.

Wide Temperature Range – Suitable for various heating applications.

Applications:

Electric Kettles – Ensures water boils at the right temperature and prevents dry heating.

Coffee Machines – Maintain brewing temperatures.

Rice Cookers & Multi-Cookers – Provides precise heat control for good cooking results.

Water Heaters & Boilers – Prevents overheating and ensures user safety.

Household and Industrial Heating Devices – Regulates temperature in a variety of appliances.

KSD301 Snap Disc Thermostats are widely recognized for their high efficiency, safety features, and cost-effectiveness, making them essential components in many temperature-sensitive devices.

About Us

Wenzhou Qianxun Electrical Technology Co., Ltd. a professional China KSD301 Snap Disc Thermostat manufacturer and wholesale KSD301 Snap Disc Thermostat factory, is located in Tiancheng Industrial Zone, Yueqing City, Zhejiang Province. Since 2014, we have been dedicated to the field of thermostats. Guided by the value of "becoming a well-known innovator and manufacturer in the thermostat industry," we have been striving for progress and have now become the industry benchmark. As a reliable domestic manufacturer of KSD301 Snap Disc Thermostat, Qianxun Electrical has cooperated with many enterprises at home and abroad, committed to providing customers with professional thermostat design, research and development, production, and sales services.

Qianxun Electrical possesses a professional R&D team and testing equipment. By integrating advanced design concepts and methods, we can now present to customers a variety of high-reliability, cost-effective patented products, including the patented Springwater Bottom Thermostats(six/five-core), adjustable thermostats, positive pressure thermostats, waterproof five-core thermostats, and steam switches, among other series of products.

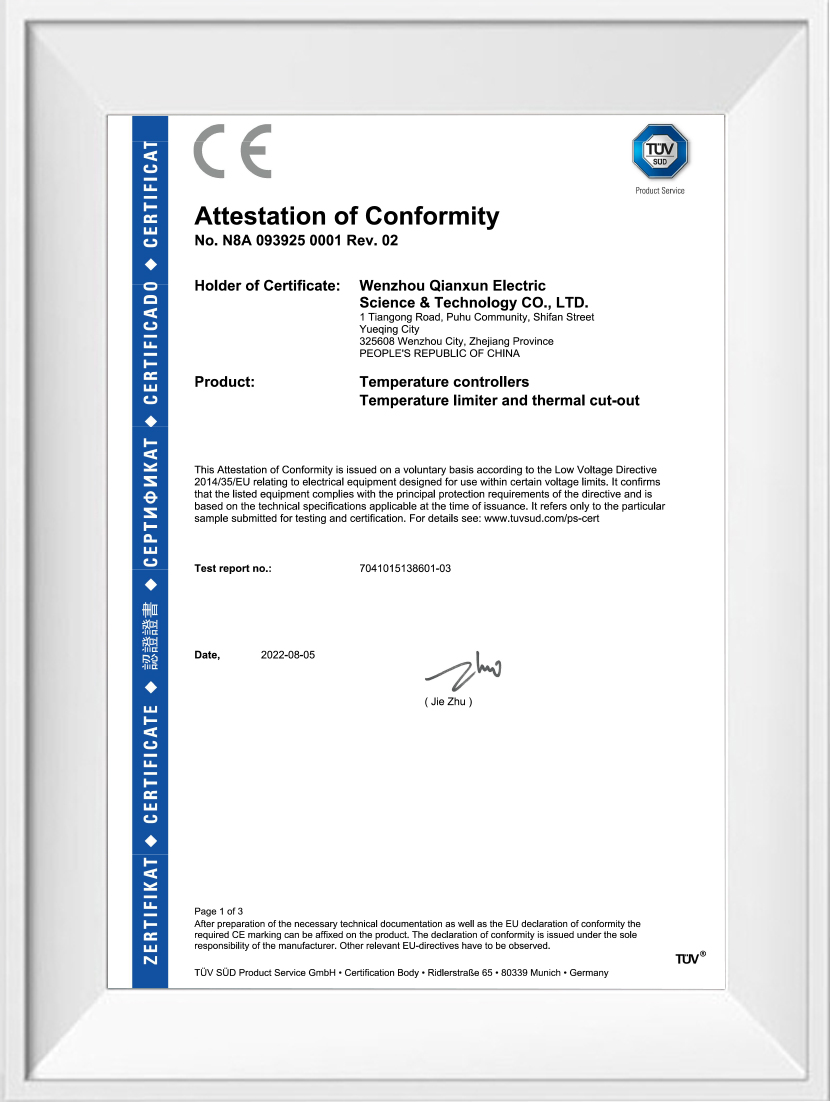

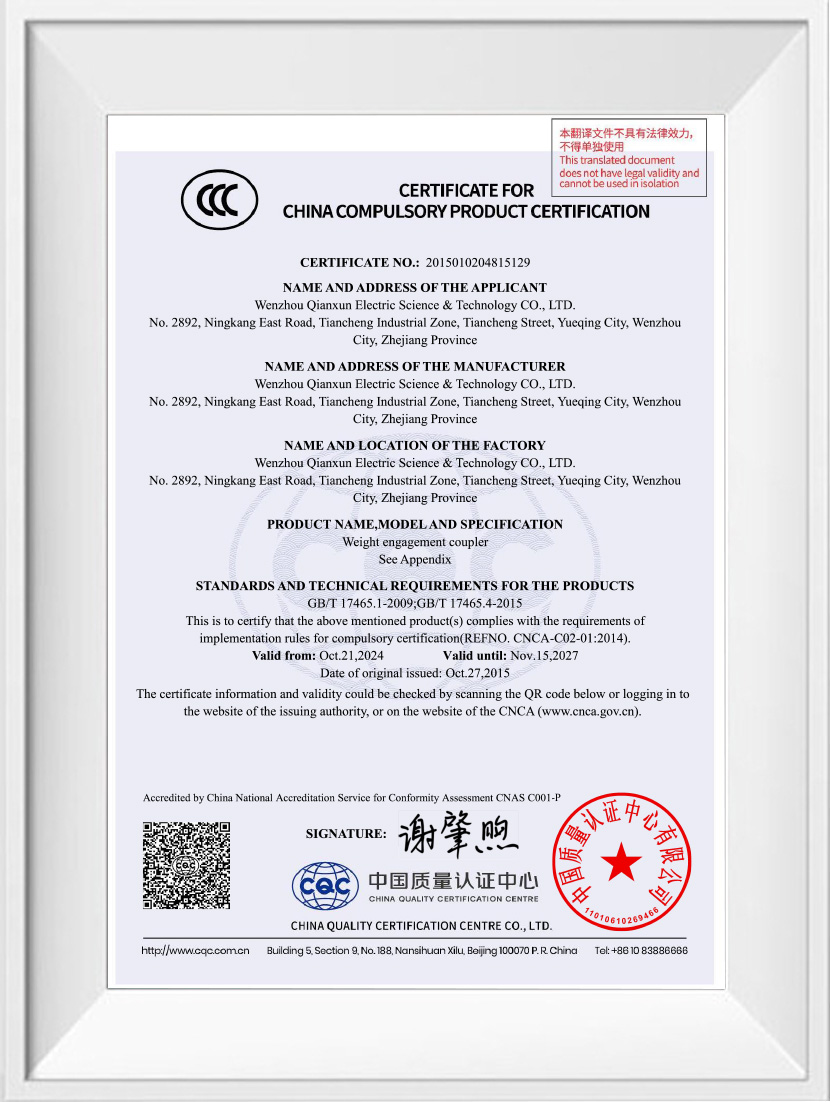

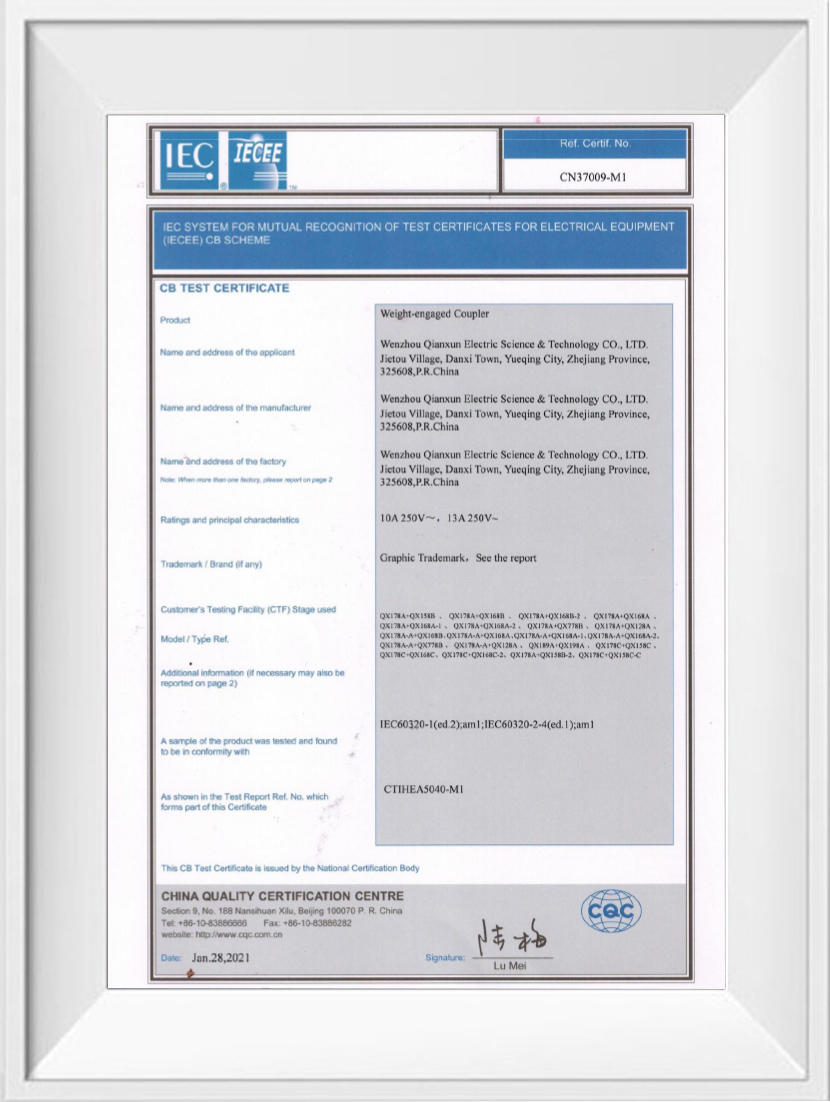

Currently, Qianxun Electrical's products have obtained the national CCC certification and the EU CE certification issued by the German TUV laboratory. Simultaneously, due to its profound technical accumulation, Qianxun Electrical is also fully capable of customizing non-standard products for use in more stringent environments and acquiring certifications such as CQC and CB for these products. Resolving customers' problems with its own technical strength is an unwavering pursuit for Qianxun Electrical.

As a reliable KSD301 Snap Disc Thermostat supplier to a wide range of customers, Wenzhou Qianxun Electrical Technology Co., Ltd. exercises stringent control over the manufacturing of its products. The professional and highly skilled quality control team performs rigorous quality checks at every small detail, from research and development, production, to the final dispatch. The material control team is responsible for supply chain management, implementing efficient procurement, storage, and distribution strategies to ensure quick product delivery. The industrialization team is dedicated to intelligent manufacturing, providing a strong guarantee for the efficiency of the production site and the stability of the manufacturing processes.

Certificates

News Center

-

Industry News 2026-01-27

Introduction to Multi-Layered Kettle Safety The Anti-Drying Kettle Thermostat is a crucial safety component in modern el...

View More -

Industry News 2026-01-23

Introduction to Dry Boil Protection The Dry Boil Protection Kettle Part Coupler is an essential safety component in mode...

View More -

Industry News 2026-01-16

Importance of Accurate Coupling The Kettle Thermostat Coupler serves as a critical interface between the kettle’s heatin...

View More

Contact us now

KSD301 Snap Disc Thermostat Industry Knowledge Extension

In the highly specialized field of kettle thermostat manufacturing, the bimetallic snap‑action thermostat produced by Qianxun Electrical Technology Co., Ltd. serves as an essential safety and control element in modern electric kettles. A typical Qianxun part, such as the widely used KSD‑301 series, combines precision thermal responsiveness with consistent mechanical performance. Built from two metals with distinctly differing coefficients of thermal expansion, the bimetal strip bends predictably when heated, and once a designated temperature is reached—commonly around 100 °C—the strip “snaps” to open the contact, interrupting current to the kettle's heating element.

A crucial consideration in thermostat engineering lies in the hysteresis range—the differential between the cut‑off temperature and the reset temperature. Qianxun controls this tolerance tightly, ensuring that once the kettle cools, the contacts return swiftly to the closed state upon meeting reset criteria. Such prompt resetting is vital in dual‑disc or auto‑reset designs that rely solely on the bimetal element, and particularly important in configurations where the thermostat also serves boil‑dry protection or oversees gradual temperature decline.

Mechanically, Qianxun's thermostats are packaged in heat‑resistant polymer or phenolic resin housings, commonly fitted with copper‑alloy terminals that are tin‑plated for oxidation resistance and low contact resistance. The housing design is also optimized for steam‑directing tubes, which channel vapor precisely onto the bimetal disc, enabling a sharp, repeatable switch response. The inclusion of a leaf spring ensures consistent contact pressure over many cycles, supporting lifecycle performance typically measured in tens of thousands of operations.

In the context of enhanced safety, Qianxun offers specialized variants that integrate dual bimetal discs or a thermal fuse. The secondary disc acts as an over‑temperature fail‑safe, activating if the primary thermal cut‑off does not trigger properly. Some designs embed a non‑resettable fuse, which permanently interrupts the circuit at a predetermined high temperature, providing a secondary layer of protection against catastrophic failure and fulfilling stringent safety standards.

From the perspective of production engineering, Qianxun's capabilities—backed by advanced assembly lines and statistical process control—ensure consistency across large production runs. The company reportedly employs automated optical inspection to verify critical components like disc curvature, spring preload, and contact alignment. Once assembled, each thermostat undergoes electrical testing that includes contact resistance verification, insulation resistance measurement, and operational testing under elevated temperature and humidity. Such robust testing regimes help to secure certifications from international safety bodies, including CE, TUV, and CB marks, and support reliability in demanding environments.

Material selection forms another pillar of Qianxun's manufacturing philosophy. The bimetal element often incorporates a copper‑nickel alloy paired with stainless steel or brass to optimize for fatigue resistance and stable expansion properties. In some premium variants, nickel plating is applied to the bimetal disc to reduce oxidation and sustain precise switching cycles over prolonged use. The combination of brass terminals and glass‑fiber reinforced housing enables high dielectric strength while maintaining compact form factors.

On the performance front, Qianxun thermostats are rated for ambient environments typical of the kettle steam chamber: high humidity, rapid temperature cycling, and frequent condensation. The housing design facilitates steam exposure while protecting sensitive internals and maintaining mechanical integrity. These components often satisfy UL 376 or IEC 60730 Class B standards, making them suitable for household appliances used worldwide.

In aggregate, Qianxun's bimetallic kettle thermostats manifest a balance of precision engineering, robust materials, and automated quality control. These thermostats fulfill both primary control functions—automatic shut‑off at boiling—and supplemental protection roles, such as boil‑dry prevention and over‑temperature cutoff. For kettle manufacturers, integrating Qianxun‑supplied thermostats delivers consistent thermal performance, regulatory readiness, and cost‑effective reliability essential in global markets.

information to be updated

English

English  中文简体

中文简体  Español

Español