Impact of Anti-Drying Kettle Coupler on Heating Efficiency

In modern electric kettles, both safety and performance are equally prioritized in product design. The Anti-Drying Kettle Coupler is one of the important safety components, designed to prevent the kettle from operating when water levels are too low. However, a common concern among users and designers is whether this protective device affects the overall heating efficiency of the appliance. Understanding how the coupler interacts with the heating system and power circuit helps clarify whether it introduces any measurable delay or energy loss during normal operation.

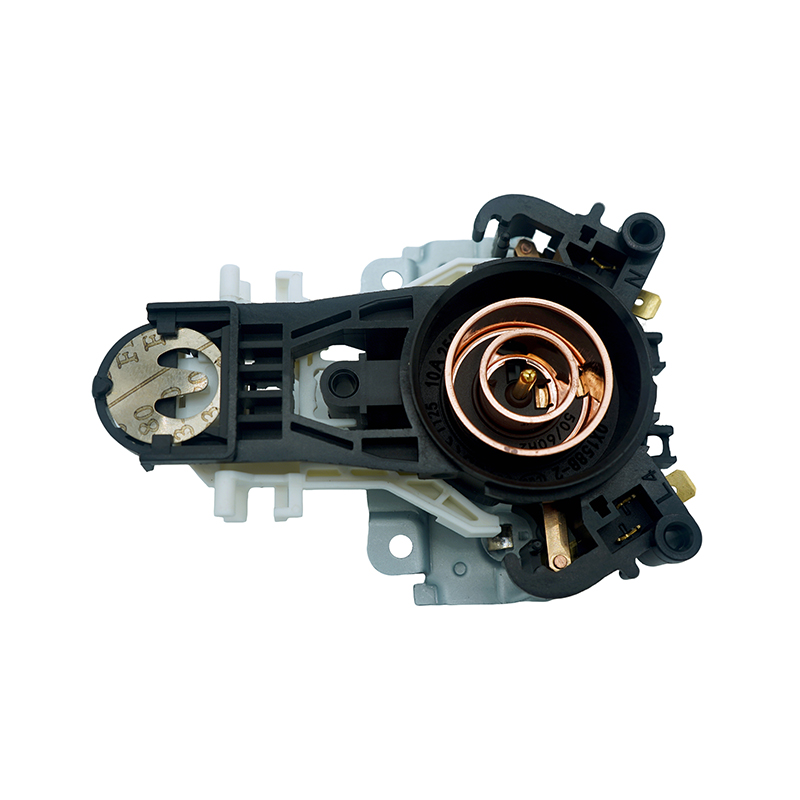

How the Coupler Integrates with the Heating System

The anti-drying coupler serves as both an electrical connector and a safety monitor between the kettle body and its base. When the kettle is properly positioned, the coupler completes the circuit, allowing current to flow directly to the heating element. This connection is engineered to maintain electrical resistance, ensuring that energy is transferred efficiently from the power source to the heating coil. High-quality contact surfaces, often made of brass or nickel-plated copper, prevent voltage drops or energy dissipation that could affect heating speed. As a result, under normal conditions, the coupler itself has little to no negative impact on thermal efficiency.

Electrical Conductivity and Heat Transfer Considerations

In evaluating the heating efficiency of electric kettles, two main factors are involved: electrical conductivity and heat transfer. The Anti-Drying Kettle Coupler is designed with precision-engineered contact points that maintain strong conductivity throughout repeated use. This design reduces the risk of micro-arcing or contact degradation that might cause energy losses. Since the coupler’s primary function is to monitor temperature rather than regulate power flow, it operates passively during heating cycles, exerting negligible influence on energy conversion. Most performance tests show that the difference in boiling time between kettles with and without an anti-drying coupler is almost unnoticeable—typically within one or two seconds.

Temperature Monitoring and System Feedback

One of the strengths of the anti-drying system is its ability to balance safety with efficiency through real-time temperature monitoring. The coupler includes a thermal sensor that measures base temperature and communicates with the kettle’s control unit. This allows precise heating control, preventing overheating while maintaining consistent energy output. In fact, by avoiding unnecessary over-boiling or excessive energy use, the coupler indirectly contributes to overall efficiency. Instead of letting the heater operate beyond a suitable temperature, it ensures the system works only within the required range, conserving energy and reducing wear on the heating element.

Material Design and Longevity Effects

The materials used in the coupler also play an important role in maintaining efficient operation. High-grade heat-resistant polymers and metal alloys are selected for their ability to sustain stable conductivity under both thermal and mechanical stress. These materials resist oxidation and carbon buildup, two common issues that can increase resistance over time. By maintaining clean contact surfaces, the coupler ensures a consistent electrical path and long-term energy efficiency. Moreover, its precision manufacturing reduces energy loss caused by misalignment or micro-gaps between connectors.

Overall, the presence of an anti-drying protection system does not compromise the heating efficiency of an electric kettle. The Anti-Drying Kettle Coupler functions as a passive yet intelligent safety component, designed to allow smooth power transmission while preventing hazardous conditions. Its high conductivity, stable mechanical design, and precise temperature feedback contribute to both safe and efficient heating performance. Instead of reducing efficiency, it enhances operational reliability and helps maintain suitable energy usage over time. Through careful engineering and quality material selection, modern kettle designs successfully achieve a balance between safety assurance and energy performance, proving that protection and efficiency can coexist without compromise.

English

English  中文简体

中文简体  Español

Español