How a Bimetal Iron Thermostat Maintains Stability Under Voltage Fluctuation

In modern household appliances, maintaining consistent thermal control is crucial to ensuring performance, safety, and energy efficiency. The Bimetal Iron Thermostat plays a central role in managing these factors within electric irons, where voltage fluctuations are often inevitable due to variations in power supply. These fluctuations can cause inconsistent heating, over-temperature risks, or even reduced component lifespan. Understanding how this thermostat reacts and compensates for unstable voltage is essential for evaluating its reliability in real-world applications. Its design cleverly utilizes mechanical and thermal principles rather than relying solely on electronic regulation, allowing it to maintain stable operation under variable electrical conditions.

Operating Mechanism Under Fluctuating Voltage

The fundamental working principle of the thermostat is based on the expansion and contraction of two bonded metal strips with different thermal coefficients. When the electric current heats the iron plate, the bimetal element bends due to differential expansion, which triggers the electrical contact to open and cut off power once a set temperature is reached. During voltage fluctuation, a rise in voltage increases current and thus accelerates heating, while a voltage drop slows it down. The mechanical nature of the bimetal reaction ensures that temperature regulation remains primarily dependent on heat transfer and material properties, rather than direct voltage response. This means that even if the voltage momentarily spikes, the bimetal element quickly senses the corresponding temperature rise and interrupts the current flow, preventing overheating.

Thermal Inertia and Self-Compensating Behavior

One of the key factors that allows the thermostat to handle voltage fluctuations effectively is its thermal inertia. The iron plate and heating element have significant thermal mass, which prevents rapid temperature changes even under short-term voltage spikes or drops. This slow response gives the bimetal component sufficient time to react accurately to the true thermal condition rather than transient electrical noise. In this way, the thermostat exhibits a self-compensating characteristic—adjusting the duty cycle of heating automatically based on real-time temperature rather than fluctuating voltage amplitude. Such inherent stability ensures that the ironing surface remains within a consistent thermal range, maintaining both performance and safety without complex electronic regulation.

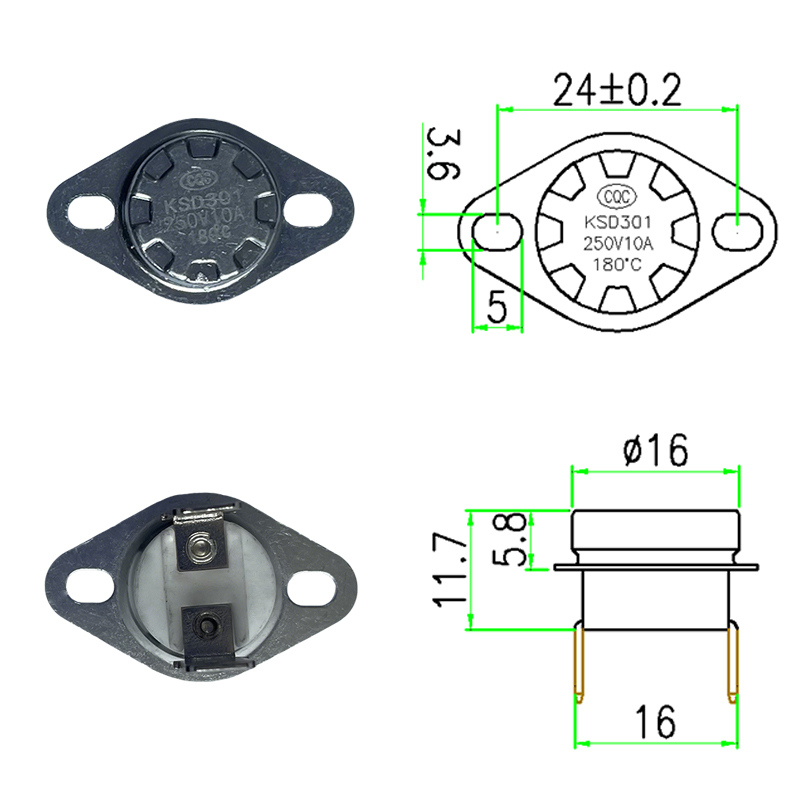

Material Selection and Contact Design

The ability of the thermostat to withstand voltage variation also depends heavily on its material composition and contact design. High-quality bimetal strips with precisely matched thermal expansion coefficients reduce the risk of delayed or premature switching. Meanwhile, contact points are usually made of silver-nickel or silver-cadmium oxide alloys, which have good resistance to electrical arcing caused by voltage surges. These design choices ensure that even under unstable current conditions, the contact mechanism operates reliably and prevents pitting or welding that could cause malfunction. The durability of the contact materials further enhances the thermostat’s lifespan, keeping its temperature control performance consistent over thousands of cycles.

Practical Performance and Energy Stability

In practical household use, where voltage may fluctuate due to grid instability or simultaneous operation of multiple appliances, this thermostat maintains a stable operating rhythm. The heating element cycles on and off in response to actual plate temperature, not just instantaneous current flow. This ensures that fabrics are ironed evenly without scorching or insufficient heating. Moreover, because the thermostat prevents excessive current draw during high-voltage conditions, it contributes to better overall energy efficiency and protection of internal circuitry. Users thus experience steady thermal output and safer operation, even when the power environment is not ideal.

Through a combination of mechanical responsiveness, thermal inertia, and durable contact materials, the Bimetal Iron Thermostat effectively mitigates the influence of voltage fluctuations on temperature control. Unlike electronic systems that may require sensors and microprocessors, it achieves this stability using simple physical principles, ensuring both cost efficiency and reliability. Its ability to maintain consistent heating under unstable voltage not only enhances the performance of electric irons but also contributes to longer appliance life and improved user safety, demonstrating the enduring value of this classic yet sophisticated thermal control component.

English

English  中文简体

中文简体  Español

Español