Comparing the Advantages and Disadvantages of Bimetal Iron Thermostats and Electronic Thermostats

When it comes to regulating temperature in appliances or equipment, two common technologies are frequently considered: the Bimetal Iron Thermostat and the electronic thermostat. Each of these devices offers unique characteristics that make it suitable for specific environments and applications. Understanding their differences is essential for selecting the appropriate option, whether for domestic appliances, industrial machinery, or commercial systems.

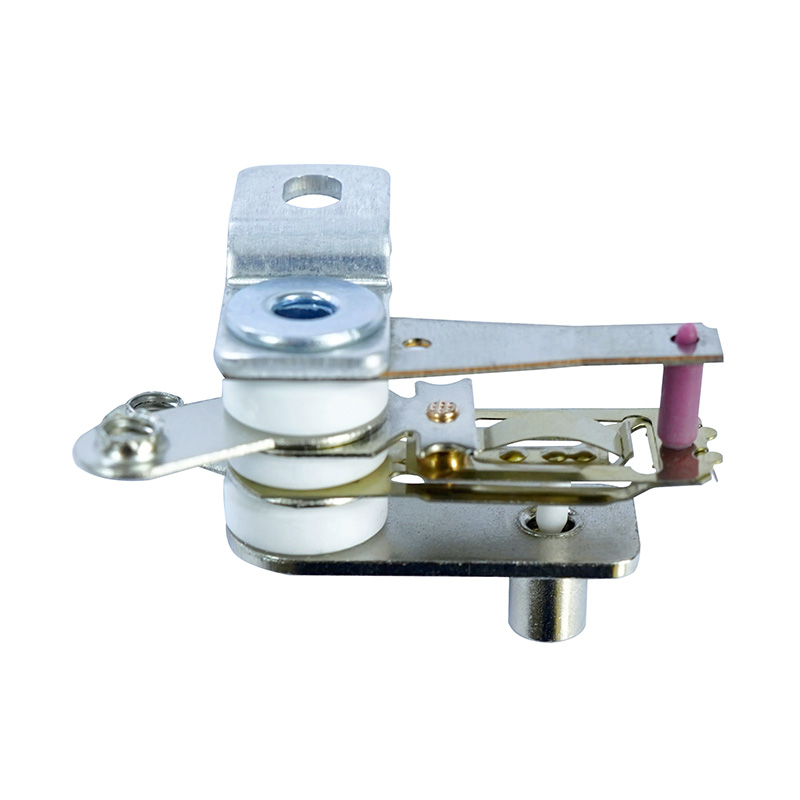

The Bimetal Iron Thermostat operates through a mechanical principle involving two metals with different expansion rates bonded together. As the temperature changes, the metal strip bends, opening or closing an electrical contact to control current flow. This design offers a simple, self-contained solution that requires no external power source for sensing temperature. Its reliability, mechanical simplicity, and cost-effectiveness have kept it in widespread use, particularly in devices like irons, electric kettles, toasters, and basic heating systems. Its durability in high-heat conditions and resistance to electrical noise also make it a strong candidate for rugged environments or situations where electrical interference is a concern.

In contrast, the electronic thermostat uses sensors, microcontrollers, and digital algorithms to measure temperature and trigger responses. These devices are highly precise and programmable, offering features such as digital displays, remote control, and adaptive temperature regulation. Because they process data quickly and can integrate into smart systems, electronic thermostats are favored in HVAC systems, programmable household appliances, and energy-efficient buildings. They offer tighter temperature control and greater versatility, especially where user interface or remote adjustments are desired.

However, each system has drawbacks. The Bimetal Iron Thermostat lacks the fine-tuned sensitivity of its electronic counterpart and may have slightly wider temperature tolerances. Its mechanical parts, though durable, are subject to wear and can become less responsive over time with extensive use. On the other hand, electronic thermostats require a constant power supply, may be more vulnerable to power surges or software malfunctions, and generally involve more complex installation and higher costs. Maintenance and replacement may also require more technical expertise, unlike the mechanical nature of a bimetal solution that can often be tested or swapped with basic tools.

Cost is another important factor in the comparison. Bimetal Iron Thermostats are significantly more affordable and easier to produce in large quantities, which makes them ideal for cost-sensitive applications. Electronic thermostats, while more expensive, offer long-term savings in energy-efficient environments where precise control can reduce waste and improve performance. In settings where consistent environmental monitoring or user customization is important, electronic options are usually good. However, for devices with straightforward temperature control needs and limited user interaction, mechanical thermostats are often sufficient.

In summary, both the Bimetal Iron Thermostat and the electronic thermostat present clear advantages depending on the intended use. The former excels in simplicity, ruggedness, and affordability, while the latter provides higher precision, programmability, and integration with digital systems. When choosing between them, engineers and product designers must evaluate not only technical specifications but also cost, reliability, user needs, and the overall operational context. Each technology holds its value and relevance in today's diverse range of temperature-sensitive applications.

English

English  中文简体

中文简体  Español

Español