Anti-Drying Kettle Thermostat: Deliver Precise Temperature Control for Stable Water Heating?

Precision in temperature control is one of the critical performance indicators. The Anti-Drying Kettle Thermostat is not only responsible for preventing dangerous dry-boil conditions but also for ensuring that water reaches and maintains a stable temperature. Users increasingly expect consistent performance whether preparing tea, coffee, or boiling water for general use. This raises the important question: can such thermostats truly guarantee temperature accuracy and stability?

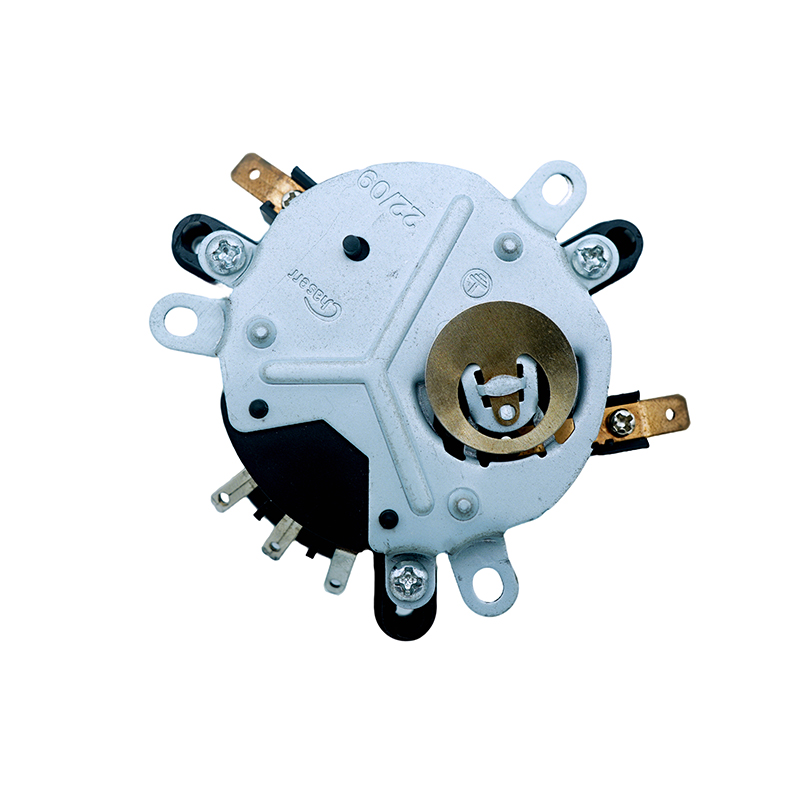

How Thermostats Function in Kettles

A kettle thermostat operates as a thermal sensor and switch combined into one component. It detects heat levels from the heating element or kettle base and disconnects the power supply once a specific temperature is achieved. Unlike simple cutoff systems, advanced models are designed to ensure a steady heating cycle, balancing between energy input and water temperature requirements. This balance is what allows a kettle to keep water at a safe and consistent boiling point rather than fluctuating significantly.

The Significance of Accurate Temperature Regulation

Stable water temperature directly impacts both safety and user satisfaction. If a thermostat is too sensitive, it may cut off power prematurely, causing underheated water that does not meet boiling standards. Conversely, if it reacts too slowly, water may overheat, wasting energy and creating excess steam. Accuracy ensures hygienic water preparation, efficient energy use, and consistent quality when preparing beverages that require precise temperatures. The performance of the thermostat, therefore, influences both functionality and long-term trust in the appliance.

Factors That Affect Precision

Several factors determine how accurately a thermostat can regulate water temperature. The quality of the bimetallic strips or electronic sensing components plays a central role, as higher-grade materials respond more predictably to temperature changes. Placement of the sensor within the kettle also matters; a thermostat that is positioned too far from the heating element may detect temperature changes with a delay. Additionally, external conditions such as ambient humidity, mineral buildup from hard water, and repeated heating cycles can gradually alter responsiveness.

Engineering Approaches for Stability

Manufacturers adopt multiple engineering solutions to achieve precise and stable temperature regulation. Some thermostats use finely calibrated bimetal components that bend at exact temperature points, while others employ electronic sensors with microcontrollers to enhance responsiveness. Anti-drying features add another layer of safety, ensuring the system never runs without water and therefore never encounters erratic heating patterns. Combined, these design strategies allow kettles to maintain reliable performance across a wide range of usage scenarios.

Testing and Quality Assurance

To validate performance, manufacturers subject thermostats to rigorous testing. This includes repeated boil cycles, varying water levels, and simulated dry-burn scenarios to ensure accuracy under stress. International safety and performance certifications often require precise adherence to temperature thresholds, meaning that compliant products must pass strict quality benchmarks. Testing ensures not only immediate accuracy but also long-term stability across thousands of operational cycles, building confidence that the kettle will perform consistently over time.

Long-Term Reliability Considerations

Even with precise engineering, durability plays an important role in maintaining accuracy. Prolonged exposure to heat, water, minerals, and mechanical wear can degrade thermostat components over time. High-quality designs incorporate materials resistant to corrosion and thermal fatigue, ensuring that accuracy remains intact even after years of use. Reliable long-term precision provides users with consistent boiling results while extending the overall service life of the appliance.

The question of whether an Anti-Drying Kettle Thermostat can guarantee stable water temperature is closely tied to its design, materials, and testing standards. Accurate sensing mechanisms, quick cutoff responses, and durable construction work together to deliver both safety and consistency. For modern households, where convenience and performance expectations continue to rise, reliable thermostats serve as the backbone of electric kettle safety and efficiency. By ensuring precise temperature control, these components provide not only protection but also the confidence that every use will result in dependable, stable water heating.

English

English  中文简体

中文简体  Español

Español